1. Precautions for the use of the ball mill pinion

a. When installing the small gear, it is necessary to adjust the matching clearance with the large gear to reach the standard of smooth operation and no noise.

b. When one side of the pinion is severely worn, the pinion can be turned over.

c. If the large gear is an old gear and the small pinion is a new gear, the tooth surface of the large gear can be properly treated according to the contact degree of the small pinion.

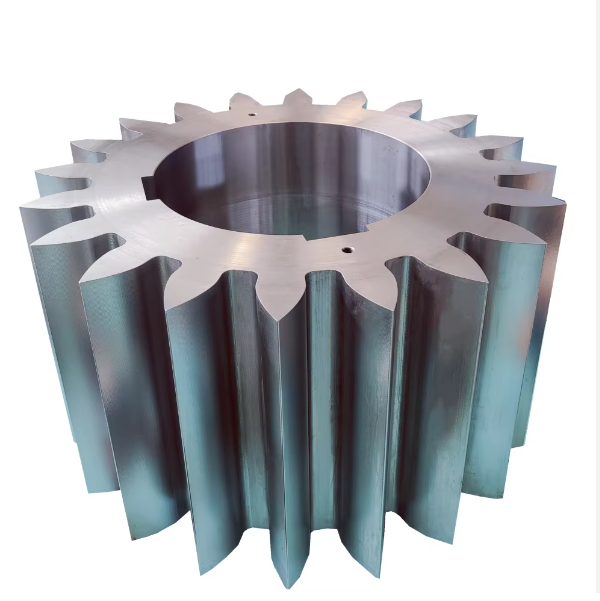

2. Tooth profile structure of ball mill pinion

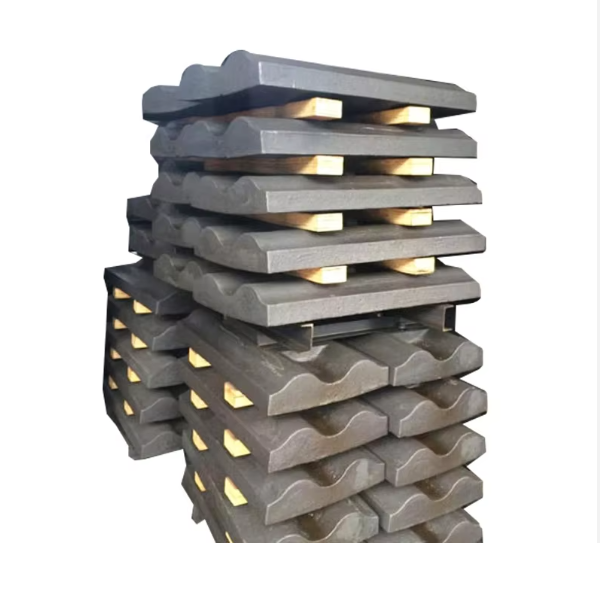

Ball mill pinion teeth are usually divided into two types, one is involute cylindrical spur gears, and the other is helical cylindrical gears. The matching spur gear enters meshing along the tooth width at the same time, which is prone to vibration and noise, and the transmission is not stable. Helical cylindrical gears are better than cylindrical spur gears in mills, and can be used for high-speed and heavy-duty with a compact center distance. However, because the manufacturing cost of helical cylindrical gears is much higher than that of cylindrical spur gears, most of the pinion of ball mills on the market use cylindrical spur gears. The connection between pinion and pinion shaft usually has expansion sleeve type and internal key type

3. Manufacturing method of ball mill pinion device

Most ball mills are driven by open gears. The pinion is a vulnerable part. It needs to be replaced with a new gear when used to a certain extent. In the past, the pinion and the shaft were keyed and hot-fitted, and the inner hole and the shaft were in interference fit; There are defects such as high dimensional accuracy requirements, difficult assembly and disassembly, and keyway weakening the strength of the shaft.

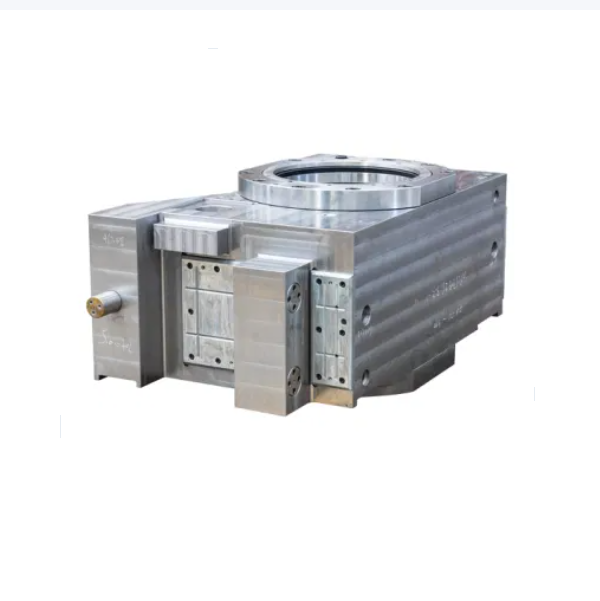

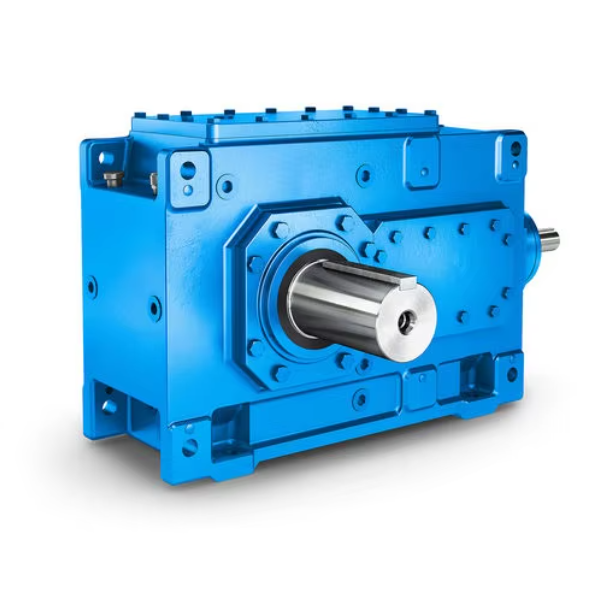

Our company provides a ball mill pinion device with simple structure, easy installation, easy disassembly and reliable performance. The purpose is a ball mill pinion device realized in this way, which is characterized in that the gear shaft and the pinion are connected by an expansion sleeve. Compared with the existing technology, it has the following advantages

Due to the structure in which the gear shaft and the pinion are connected through the expansion sleeve, the structure is simple, easy to install, easy to disassemble, and reliable in performance.

Detailed description

The gear shaft and the pinion are connected by an expansion sleeve. When assembling, first install the expansion sleeve on the gear shaft, then install the pinion on the outer circle of the expansion sleeve, adjust the position of the pinion on the shaft, and then use a torque wrench to tighten the expansion sleeve symmetrically and evenly. The bolt is fine. When disassembling, loosen the bolts on the expansion sleeve and the pinion gear can be removed.

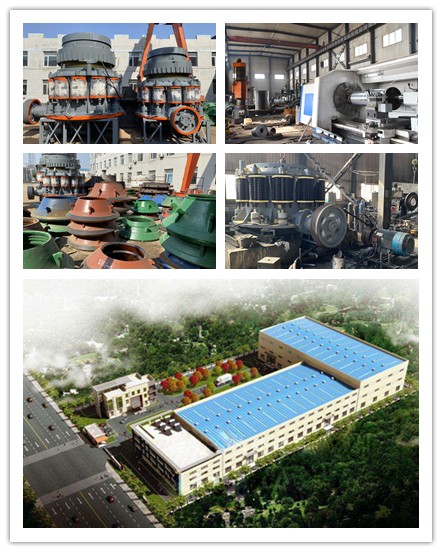

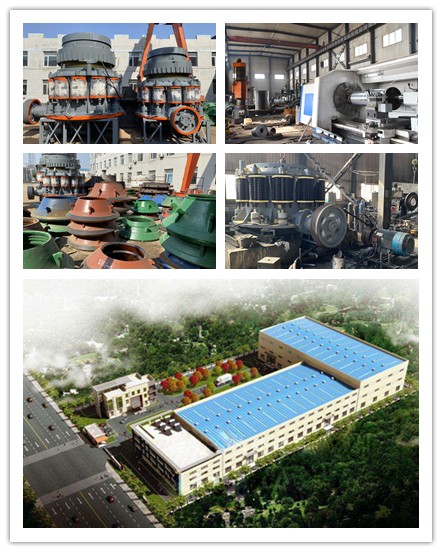

ShiLong Company Profile

Shenyang ShiLong Mechanical Manufacturing Co., Ltd. was established in 2000. It is a comprehensive enterprise dedicated to the production of mining machinery and spare parts.

As a manufacturing enterprise focusing on mining equipment and products, ShiLong is committed to building a global professional manufacturing factory. Shilong has more than 300 lathes, boring machines, milling machines and various CNC processing equipment and has more than 30 professional and technical personnel! And has a large warehouse of nearly 3000 square meters.

For 20 years, ShiLong has manufactured more than 1,000 kinds of mining equipment and related spear parts for more than 3,000 domestic enterprises and foreign trade companies. The products mainly cover multi-cylinder hydraulic cone crusher, heavy hydraulic cone crusher, single-cylinder hydraulic cone crusher, symons cone crusher, jaw crusher, gyratory crusher, ball mill, high-pressure roller mill and their spear parts.

The product quality is reliable, the performance is good, has won widespread praise.

ShiLong looks forward to working with you to create the future together!