Manufacturing method of spiral tube sealing device of ball mill

Currently ball mill inlet and outlet spiral pipes are sealed with filler type, such as installing wool felt, fiber braided packing or rubber strips in the sealing groove, but in actual use, wool felt is inelastic and only depends on its volume Packing and sealing, packing and rubber strips are easy to wear, make the gap larger, and often leak powder, which not only fails to meet the sealing requirements, but also increases maintenance costs.

Our company designed a ball mill spiral tube sealing device, which can effectively solve the powder leakage phenomenon of the ball mill spiral tube, increase the service life of the seal, and reduce the maintenance cost.

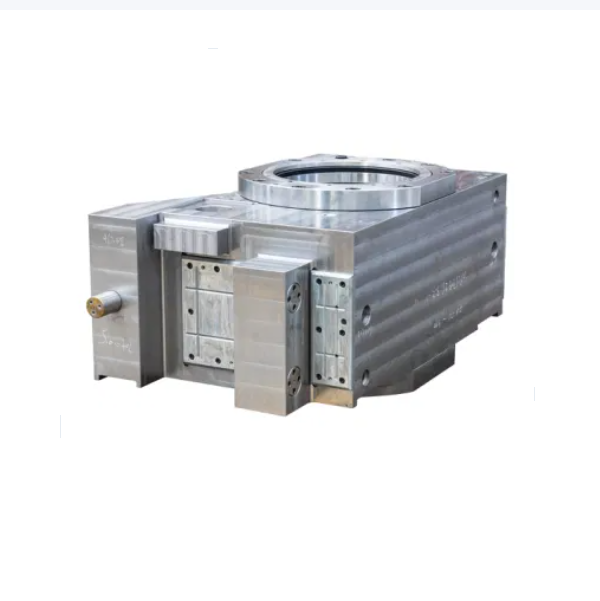

The purpose of the new type of sealing device is to achieve a ball mill spiral tube sealing device, which is characterized by installing a compound ring seal made of polymer composite material in the filler cavity at the tail of the spiral tube and at the outer end of the cavity. This ring seal The ring forms two annular sealing surfaces in the packing cavity and the outer end of the cavity; in addition, located on the outside of the tail end of the spiral tube, an elastic compensation mechanism is installed outside the circumference of the short tube. The main body of the elastic compensation mechanism is a metal support ring. It is a pair of half-open upper and lower half rings, after closing and covering the short connector,

The two ends of the ring are fixed by bolts to form a whole ring. At the lower part of the two sides of the ring, the upper, lower, front and rear circumferences are evenly distributed and welded to the support plates parallel to the short joint pipe, and the support plates are opened. Install the bolts in the holes, tighten the bolts symmetrically, and position the support ring tightly on the short tube. Then, on the upper part of the side of the support ring facing the ring seal ring, evenly weld and install the support sleeves for each support sleeve On the support ring, correspondingly open the screw holes and install the adjustment bolts with the polished rod in the front section. The polished rod section of each adjustment bolt is inserted into the support sleeve through the screw hole.

Then, slide a spring seat on the polished rods of the bolts in each support sleeve, slide a small sleeve with a pressure plate in the through hole at the other end of each support sleeve, and slide the spring seat in the hole of each small sleeve Compression springs are installed between them, and the pressure plate is tightly pressed on the outer surface of the annular seal ring, so that the small sleeve is positioned on the inner diameter of the support sleeve and moves axially in the support sleeve with the action of the compression spring. Adjust the adjusting bolts uniformly to make each compression spring press against the pressure plate, and the pressure plate compresses the annular sealing ring. When the sealing surface of the annular sealing ring becomes larger due to abrasion, the compression spring stretches to compensate effectively in time to ensure a sufficiently small gap Therefore, the powder leakage phenomenon of the spiral tube of the ball mill is effectively solved, which not only improves

the service life of the seal, but also reduces the maintenance cost.