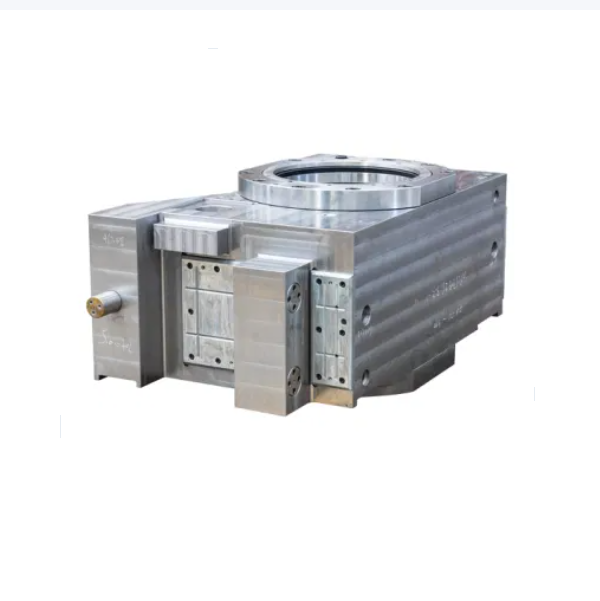

Ball Mill cap

-

SHILONG

-

Shenyang,China

-

1~2 month

-

1000 set / year

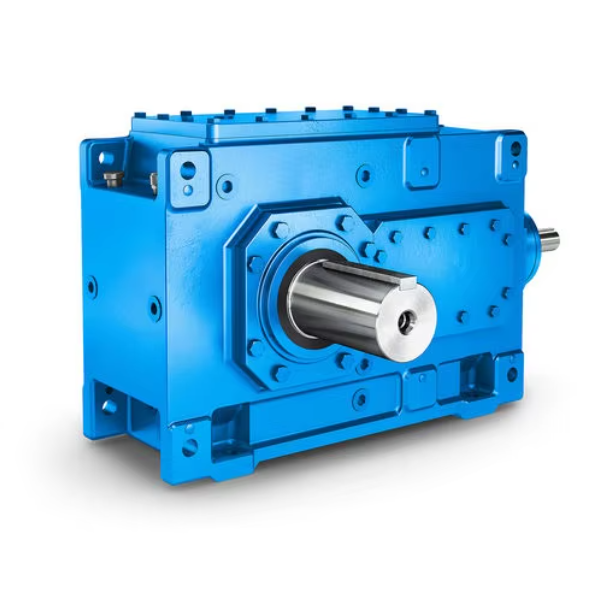

1. ShiLong ball mill feeder Cap Modle:ceramic ball mill feeder Cap, intermittent ball mill feeder Cap, over flow ball mill feeder Cap, lattice ball mill feeder Cap, wind discharge ball mill feeder Cap, double chamber ball mill feeder Cap, energy-saving ball mill feeder Cap.

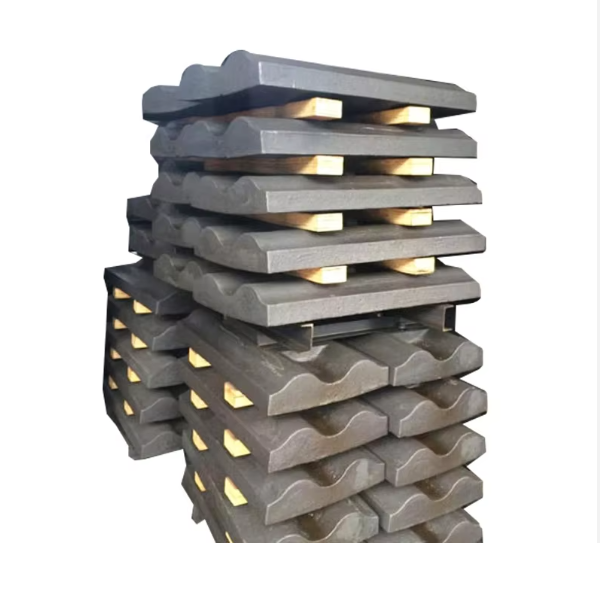

2. ShiLong ball grinder mill feeder Cap Manufacturing Process: a. drawing inspection > b. wood type making > c. casting > d. tempering > e. roughing maching > f. tempering > g. finishing maching > h. CNC maching > i. coloring flaw testing > j. ultrasonic flaw testing > k. three coordinate detection > l. coloring flaw testing > hardness testing

3. ShiLong ball grinding mill feeder Cap Testing: Provide Metallographic, machinery performance, hardness, ultrasonic inspection, coloring flaw testing, ultrasonic flaw testing.

4. ShiLong ball grinder mill machiner feeder Cap Payment Terms:L/C, T/T, D/P

6. Ball mill feeder Cap Materical : As Clients' requirements.

7. ShiLong ball mill feeder Cap Certification: CE, ISO 9001:2000, ISO 9001:2008