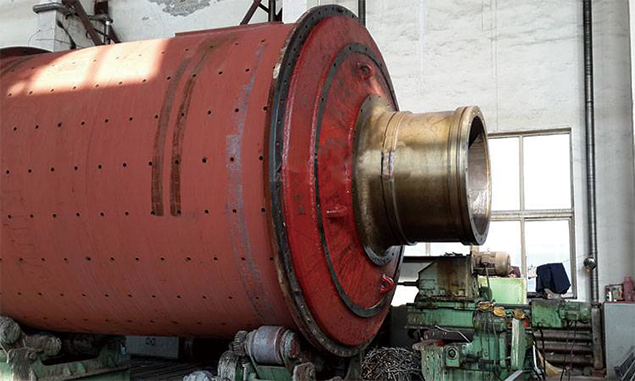

1. Precautions for the use of ball mill shell

a. When the mill is stopped for a long time, the cylinder needs to be supported by a jacking device.

b. Regularly check the wear of the liner to prevent wear through the liner.

2. Analysis and research on the ball mill shell

Most domestic researches on the ball mill shell are treated as static equipment. The strength analysis of the shell under normal working conditions is relatively small, and the study on the dynamic characteristics of the barrel and the vibration caused by impact is less involved. In order to study the dynamic conditions of the cylinder under any time-varying load, it is necessary to conduct a kinetic analysis of the cylinder, and study the dynamic conditions of the stress and strain of the cylinder under normal working conditions. The kinetic energy process under mechanical load has a clearer and clearer understanding. Thereby improving the design level of the equipment and improving the reliability of its operation.

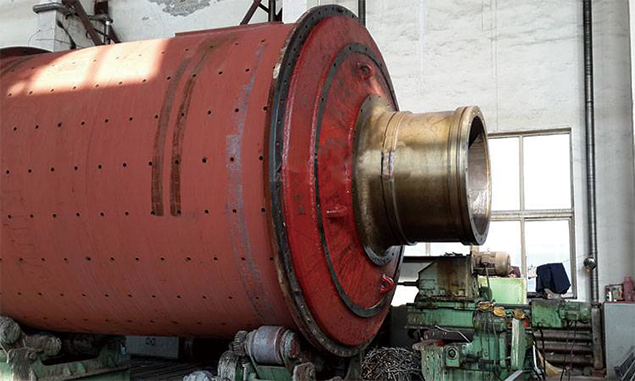

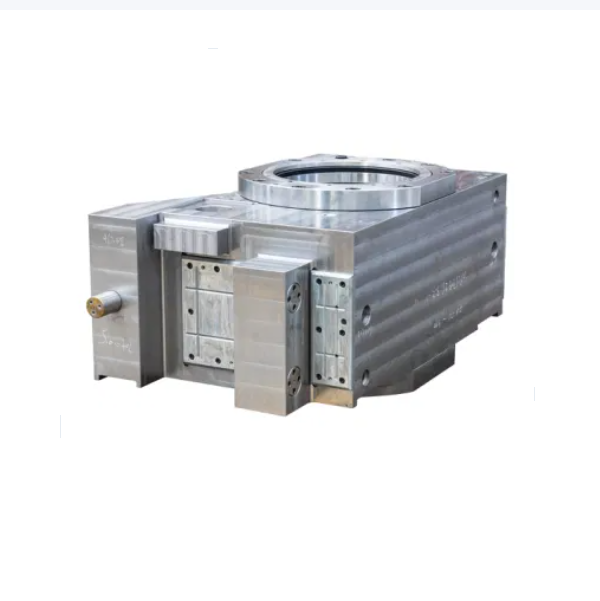

1) The structure and parameters of the cylinder

We take the ball mill cylinder of a steel mill as the research and analysis object. The main technical parameters of the barrel: the diameter of the barrel is 5m, the length is 4m, and the effective radius of the barrel is R=2.5m. The weight of the steel ball in the cylinder is 25t, and the weight of the material is 130t, so the total weight of the medium in the cylinder is 155t.

2) Conventional finite element analysis method of ball mill barrel

According to the conventional method, the mechanical model of the cylinder is generally simplified into three typical working conditions of full load static, normal working and starting for analysis and calculation. This article only discusses what works normally.

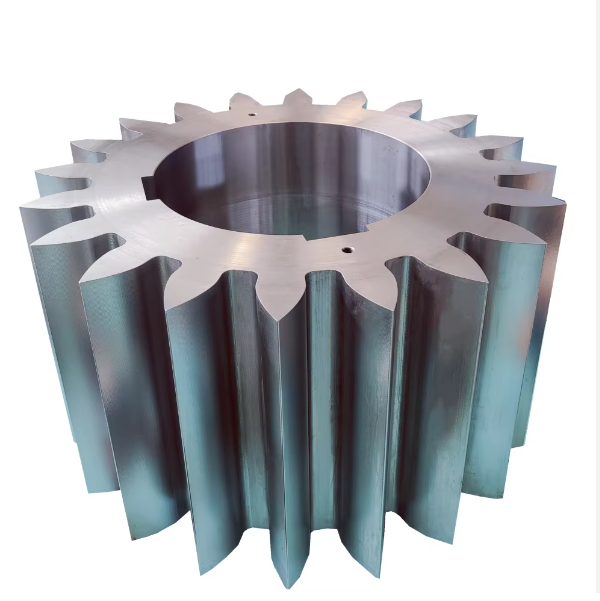

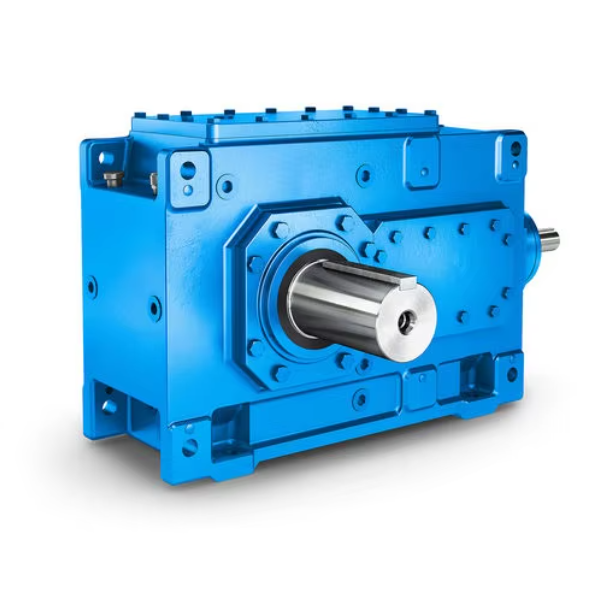

The load under normal working conditions includes the weight of the cylinder structure, the gravity of the steel balls and materials that move with the cylinder, the centrifugal force generated by it, and the gear transmission load. According to the reference, the weight of the medium directly acting on the inner wall of the cylinder, the coordinate of the center of mass and the centrifugal force produced can be calculated.

The equivalent stress distribution law of each part of the cylinder body during normal operation. Among them, the maximum stress is 85.8 MPa, which is located at the place of the trunnion ring on the hollow journal, but the stress in other parts such as the big gear and the cylinder is very small. The maximum displacement is 1.117mm, which appears on the large gear, and the cylinder also has a larger displacement. Relatively speaking, the hollow shaft journal has a smaller displacement. According to the strength limit of the material, it can be concluded that the various parts of the cylinder meet the requirements of strength and rigidity under normal working conditions.

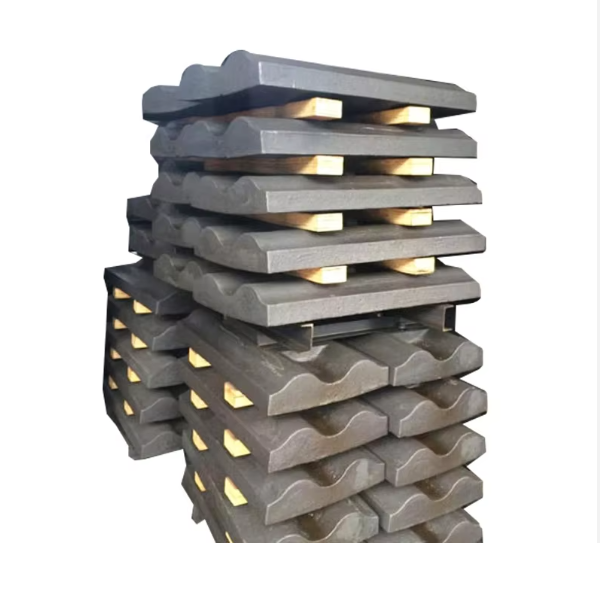

3) Ball mill shell

The previous article uses conventional ideas to analyze the strength and stiffness of the ball mill shell. It is an effective mechanical analysis method and provides an important basis for the design of the shell With the continuous improvement of modern mechanical design level, as a large-scale impact equipment, the designer pays great attention to the dynamic and vibration conditions of the cylinder under normal working conditions based on the strength and rigidity check, so it is necessary to further analyze it .

In order to study the condition of the cylinder under any time-varying load, it is still difficult to theoretically obtain the dynamic load generated by the cylinder during normal operation. The medium in the cylinder has three main moving states: the falling state, the falling state and the centrifugal state. The falling state is the main working state of the medium. In order to more truly reflect the dynamic response of the cylinder under impact load under normal working conditions, the impact area of ??the cylinder is taken as the analysis object.

Since the cylinder is a revolving body, and the motion conditions of the materials on different vertical sections in the axial direction are completely similar, the time history load on the cylinder is the same for any point on the cylinder. In order to express the impact load on the cylinder, a certain section of the cylinder is taken as the analysis object, and time history load is applied to all the nodes in it, and since the corresponding longitudinal node group enters the impact area first, the subsequent node groups enter in turn , The corresponding longitudinal node group finally enters the impact area, so when the time history load is applied, the action time of the subsequent node group load is sequentially delayed. The specific delay time is calculated as 0.044 according to the division of the nodes and the rotation speed of the cylinder. s, which scientifically simulates the actual dynamic impact load of the cylinder. Therefore, the load on the cylinder is the combination of the dynamic impact load, the cylinder's own weight, the gravity and centrifugal force of the medium in circular motion, and the gear transmission load.