1. The function and selection principle of ball mill cylinder liner

In order to protect the inner surface of the ball mill barrel from the abrasion of the grinding body and materials, a certain thickness of liner is installed on the inner wall of the ball mill barrel to effectively control the movement track and distribution of the grinding body in the barrel. The cylinder liner must be wear-resistant and the surface geometry is appropriate; the layout and connection methods are simple to shorten the time of liner disassembly and installation, reduce the leakage and shutdown caused by the liner bolt fracture, and improve the operation rate of the ball mill; The liner specifications are convenient for spare parts management and reduce operating costs.

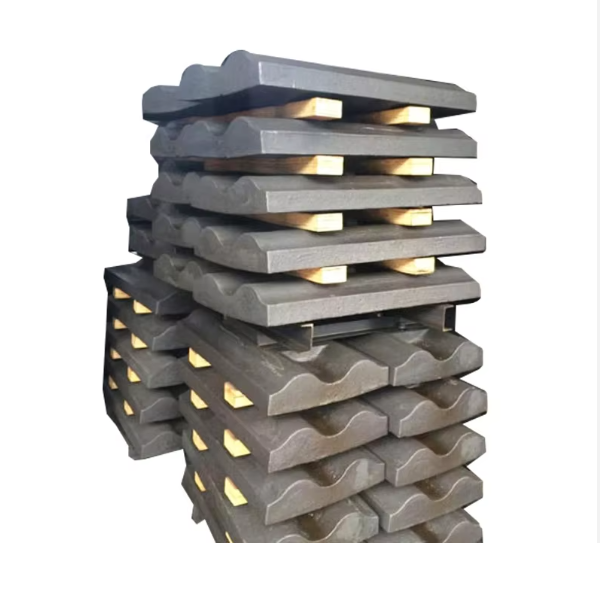

2. Nommonly used type of ball mill barrel liner

According to the surface shape of the liner, the liner can be roughly divided into two types: smooth and non-smooth: the one with less unevenness is called the smooth liner. The smooth liner has a lower impact force due to the lower lift of the steel ball, but the steel The ball slides more, the grinding and stripping effect is strong, and it is mostly used for fine grinding; the uneven liner is called the uneven liner, the uneven liner can lift the steel ball higher, obtain greater impact force, and Balls and materials have strong agitation and crushing effects, and are mostly used for coarse grinding. There are many types of rough liners, such as ribbed liners, large wave liners, step liners, graded liners and rudder liners.

3. The axial layout and connection method of the ball mill cylinder liner

The optimized design of the ball mill barrel lining plate is also very important. After the ball mill barrel lining plate is installed, it is necessary to prevent the material from forming a circulation on the inner wall of the barrel and rapidly eroding and wearing the inner wall of the shell during operation. Make full use of the geometric shape and arrangement of the working surface of the liner to control the movement track and distribution of the grinding body in the cylinder.

The T-shaped staggered layout is the traditional axial layout of the cylinder liner, which can eliminate safety hazards such as erosion and abrasion caused by the material circulation on the inner wall of the cylinder. This arrangement structure is simple, the lining plate specifications are few, the interchangeability is good, the manhole lining plate does not need special specifications, and the distribution of the screw holes on the cylinder is also regular and simple.

The above-mentioned ball mill shell adopts a single liner plate, which is directly fixed on the shell with bolts. It can be disassembled and installed in a single piece and is easy to replace. However, the bolt holes are required to be sealed and the bolts are prevented from loosening to avoid slurry leakage and bolt breakage.

Shilong makes unremitting efforts to build a better ball mill, and welcomes users in need to inquire and order.