1. What is Multi Cylinder Hydraulic Cone Crusher Mian Frame ?

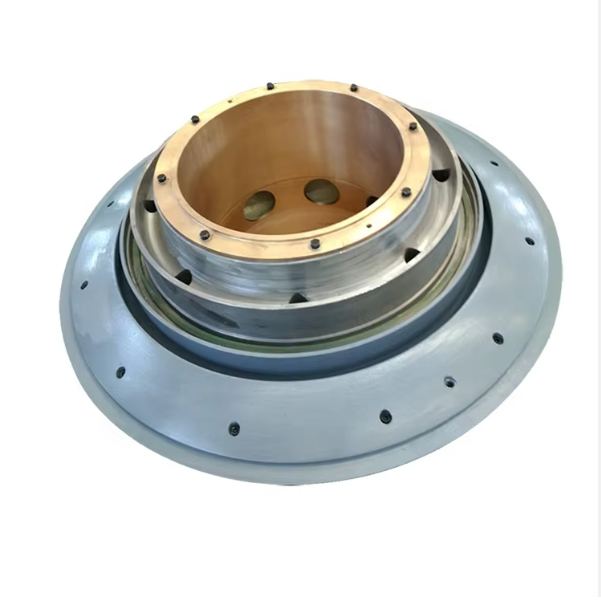

The HP Cone Crusher Mian Frame installed on the foundation of the cone crusher is usually called the cone crusher frame.

2. The role of the crusher HP Cone Crusher Upper Frame.

a. Fix the HP Cone Crusher adjustment ring par and the HP Cone Crusher bowl part.

b. As the carrier of power transmission, the frame is one of the most important parts of the cone crusher.

3. Precautions for the use of Multi-Cylinder Cone Crusher Mian Frame.

a. Regularly check the wear of the crusher Single Cylinder Cone crusher outer liner and the inner liner of the frame to prevent wear and leakage.

b. The leaks of the cone crusher frame are often found in the oil bottom groove, transmission part, and bowl-shaped support.

4. Manufacturing method of easy-to-assemble Multi-Cylinder Hydraulic cone crusher frame designed and manufactured by Shilong

The HP cone crusher is one of the crushers. It is suitable for the crushing of raw materials in the metallurgy, construction, road construction, chemical and silicate industries. According to the different crushing principles and the different particle sizes of mass products, they are divided into many model. Crushers are widely used in many field such as mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The cone crusher is suitable for medium and fine crushing of various ores and rocks because of it has large crushing ratio, high efficiency, low energy consumption and uniform product size.

Working principle: During the working process of the cone crusher, the motor drives the eccentric sleeve to rotate through the transmission device, and the moving cone rotates and swings under the force of the eccentric shaft sleeve. The section of the moving cone near the static cone becomes the crushing cavity. The material is crushed by multiple squeezing and impacts of the moving cone and the static cone. The material that has been crushed to the required particle size there falls under its own gravity when the moving cone leaves this section and is discharged from the bottom of the cone.

The structure of cone crusher generally includes a lower frame and an upper frame body arranged on the lower frame body. In order to facilitate assembly, Shilong has designed and manufactured an upper frame body in a gyratory crusher, which includes a frame body, the frame body The axial diameter of the frame gradually increases from the lower end to the upper end, and the frame body is hollow. The upper and lower ends of the outer edge of the frame are respectively provided with left-right symmetrical fastening bosses, and the fastening bosses are provided with threaded holes.

The advantage of the upper frame in this gyratory crusher:

The original main frame body composed of two halves is improved into an integrated upper frame body, which solves the difficulties in assembly and does not have problems such as positioning errors. Compared with the original design, the processing process is reduced a lot. The finishing process greatly reduces the production cost, improves the work efficiency, and improves the stability of the machine.