1. Precautions for the use of multi-Cylinder Hydraulic Cone Crusher Head

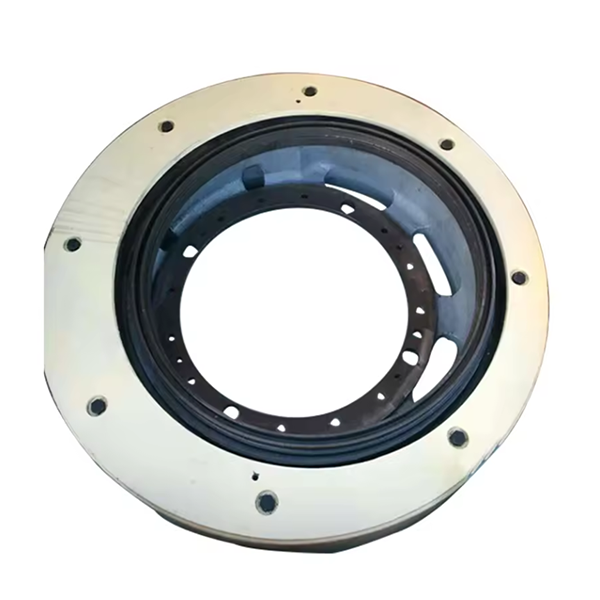

a. If oil leakage occurs at the upper or lower end of the broken wall, the oil leakage point will appear at the blockage of the cone process hole.

b. When overhauling the crushing part on site, it is necessary to observe whether the bottom hole of the spindle is blocked.

c. According to the wear of the broken wall, replace the broken wall in time to prevent the body from being worn out.

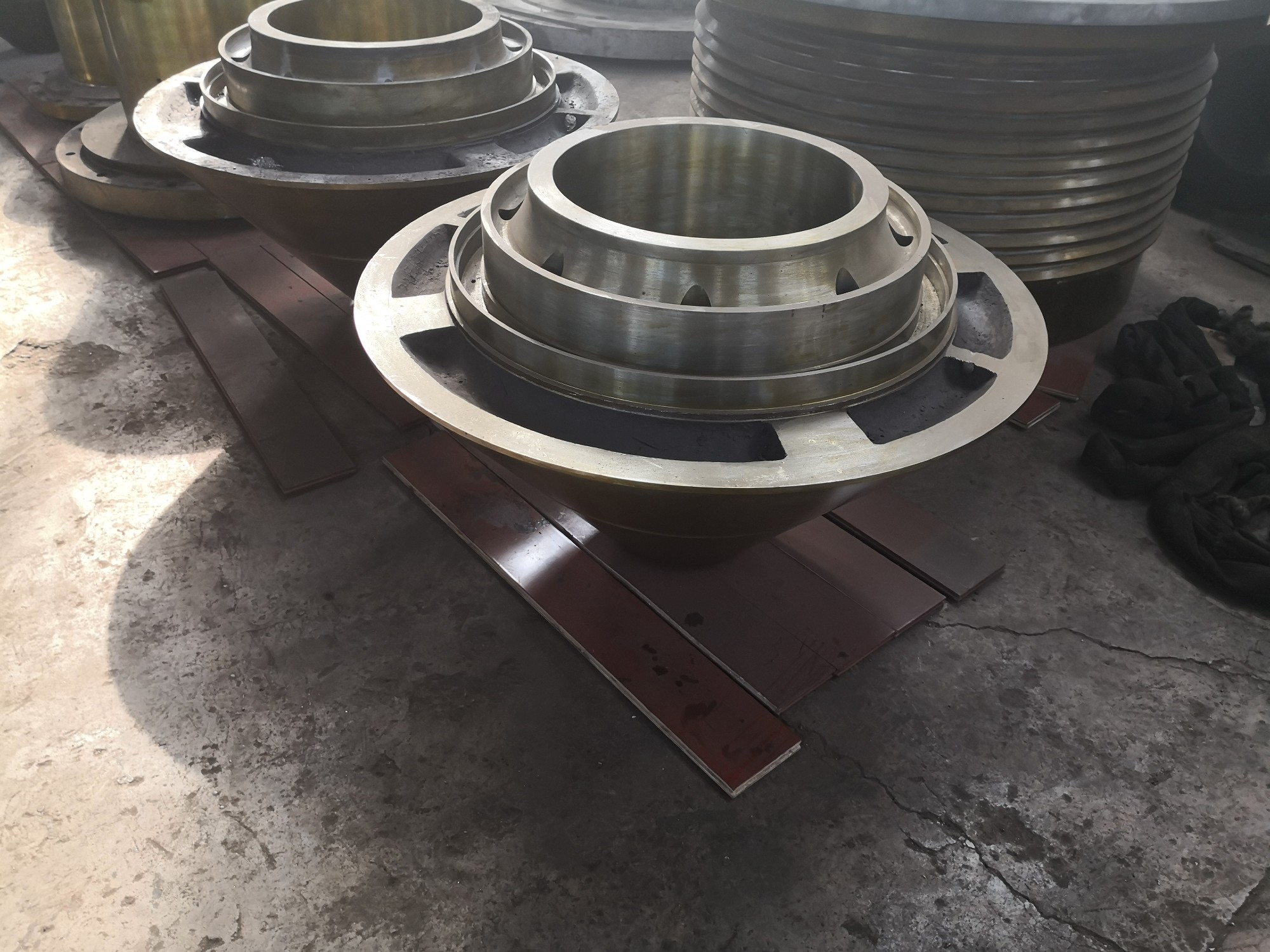

2. Making method of multi-Cylinder Cone Crusher Head

The existing cone crusher has an eccentric cone, large weight, volume, small eccentricity, and has a counterweight as a whole, which is not easy to disassemble.

The purpose of the new body is to provide an eccentric cone of the cone crusher with light weight, small size, large eccentricity, and separate from the counterweight.

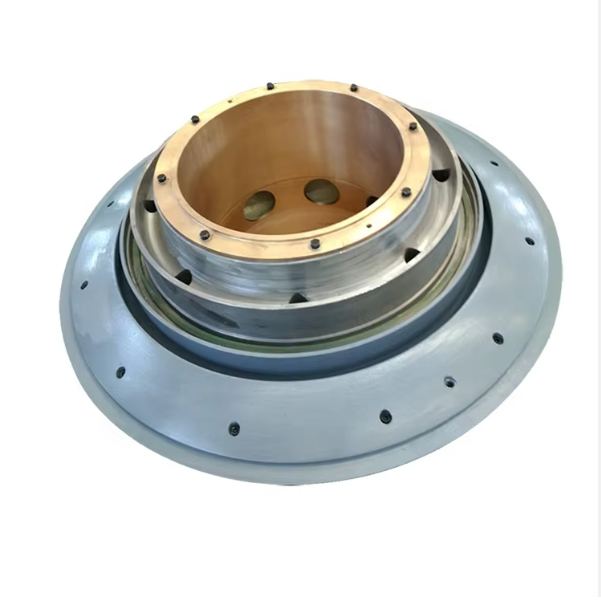

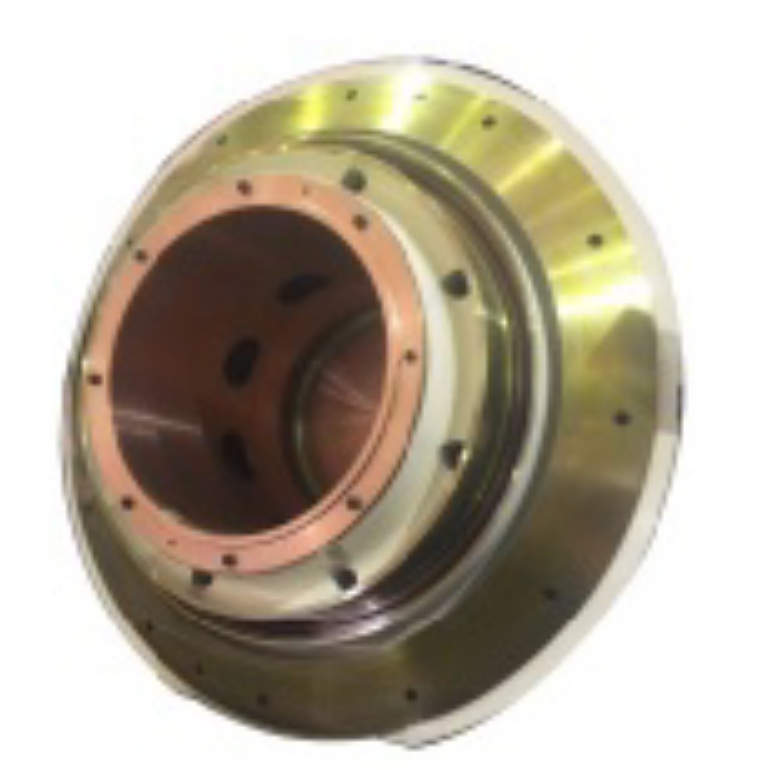

The eccentric cone of the new cone crusher is characterized by the main shaft sleeve, the eccentric cone, the connecting flange, the connecting hole and the matching cone. The eccentric distance between the main shaft sleeve and the upper end of the eccentric body is 44mm, and the deviation is within ±5mm. The vertical included angle of the cone is 2.5°, and the deviation is within ±1°. The upper part of the mating body is connected with the eccentric body, and the lower part is connected with the connecting flange. There are connecting holes around the connecting flange. The main shaft sleeve penetrates the eccentric body, For connecting flange, the inner diameter of the spindle sleeve is 520mm, and the deviation is within ±10mm, and the outer diameter of the eccentric body is 790mm, and the deviation is within ±10mm.

The advantages of the new cone are that the utility model is light in weight, small in size, large in eccentricity, and has a separate structure with the counterweight, and is convenient for disassembly, assembly, and maintenance.