In order to form a lubricating oil film, manufacturing and assembly errors, thermal expansion and force deformation of components, determine the gap between the main shaft and the tapered bushing. If the gap is too small, it is easy to hold the shaft. If the gap is too large, the service life of the machine will be reduced and shock and vibration will easily occur. The best point of the clearance between the cone bushing and the main shaft is: the upper journal is large and the gap is small, and the lower journal is small and the gap is large. This is determined by the rotation of the main shaft of the HP cone crusher around a certain point in the space.

1. The role of the Multi-Cylinder Hydraulic Cone Crusher eccentric bushing

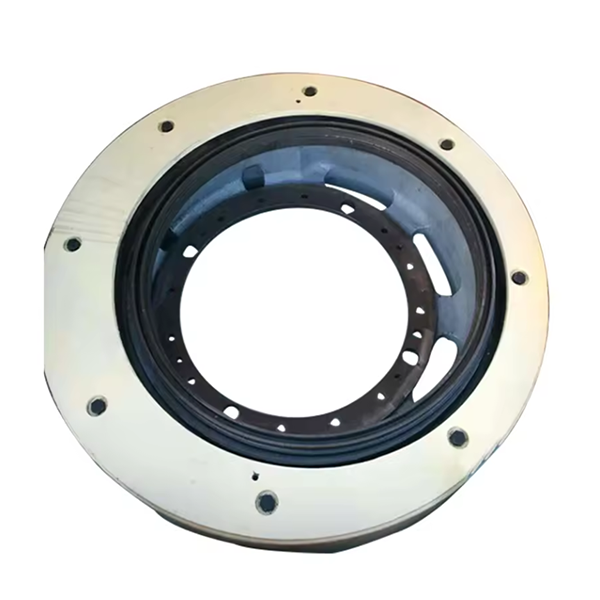

The multi-Cylinder Hydraulic Cone Crusher Innner Bushing of the cone crusher can effectively protect the steel parts in contact with it from wear, and it is easy to replace when the copper parts are worn. The installation part of the main shaft bushing is located between the main shaft of the crusher and the eccentric sleeve, and the pressure is very large. Its material and size requirements are relatively high, especially the clearance between it and the main shaft and the steel eccentric sleeve is the most important Due to the manufacturing and installation errors, it is easy to cause the cone crusher spindle to crack or even break, and the cone bushing cracks and other vicious equipment accidents during operation. Therefore, choosing the material and processing size to ensure that the spindle bushing is the key to the normal operation of the equipment.

2. Reasons for rupture of HP series Cone Crusher Innner Bushing

The spherical bearing is in contact with the spherical surface of the moving cone and receives force when the cone crusher is working. G is the weight of the moving cone itself, Fg is the inertial force during rotation, and the resultant force is the normal contact between the spherical surface of the moving cone and the matching belt of the spherical shoe. Angle and larger and smaller angles.

The restraining reaction force of the inner cone bush of the eccentric cone bush is F. , The direction horizontally points to point d on the main axis of the moving cone (mechanical model convention: ignore the vertical axis taper analysis of the moving cone according to the cylindrical axis), and translate ^ and F along their lines of action to the intersection point e of the two lines of action, according to the principle of three forces It can be seen that there must be three forces to balance it, that is, the restraining reaction force A of the spherical bearing on the moving cone, and its direction is along the normal line of the point b on the sphere to the moving cone. 0 is the center point of the moving cone.

If the spherical bearing is improperly scraped during maintenance, the inner ring of the spherical bearing is higher than the outer ring, that is, F, acting on point a, the moving cone sphere is supported on the inner ring of the spherical tile, which destroys the stable working conditions of the moving cone and changes The normal running trajectory of the cone. The main shaft will collide with the lower part of the cone bushing when the equipment is running. At this time, F, acting on point c, exceeds the larger contact angle of normal contact, and the moving cone sphere leaves the spherical bearing.

With the tendency of tipping over, the main shaft and the cone bushing are in contact with each other locally, resulting in stress concentration, which increases the wear rate of the lower end of the cone bushing and even breaks. If the clearance of the lower mouth is not adjusted correctly during repair, the main shaft will partially contact the lower mouth of the cone bushing when the crusher is running, causing stress concentration, which will damage the cone bushing and make the moving cone unstable. In addition, making the eccentric shaft sleeve or the cone bushing skew during the overhaul of the crusher will also cause the main shaft to contact with the lower mouth of the cone bushing and cause damage to the cone bushing.

The main reasons are: ①The thickness of the adjustment gasket added when the tooth gap is adjusted is uneven; ②The thrust plate wears unevenly; ③It is too heavy to deflect the cone bushing; ④The round pin does not completely enter the pin hole at the bottom of the eccentric bushing. Make it tilt. When there is a load, under the action of the crushing force, the cone bushing cannot return to the normal position, resulting in lower mouth wear. It is precisely because the cone bushing cannot return to the normal position under load, the lower end of the spindle presses against the lower mouth of the cone bushing. At this point, the lower mouth of the cone bushing is locally loaded, and M will crack over time.