1. The role of muti-Cylinder Hydraulic Cone Crusher Pinion

The torque of the motor is transmitted to the big gear through the HP series Cone Crusher Pinion, and the rotation of the gear is brought to the crushing part to crush the material.

2. Precautions for the use of Multi-Cylinder Cone Crusher Pinion

a. Please pay attention to leaving a working gap of 4~5mm on the left and right sides of the transmission shaft during assembling the pinion.

b. it is advisable to pass a 3~4mm gap between the teeth when you are adjusting the working gap between the pinion and the gear of the hp cone crusher.

c. Try to ensure that the indexing outer circles of the big gear and the small gear are tangent.

d. It is necessary to check the straightness of the countershaft after the pinion has passed the iron and punched the teeth.

3. The function and maintenance of HP series Cone Crusher Pinion

The pinion gearbox of the cone crusher is an important transmission device and the only way for the cone crusher to obtain a crusher. The main shaft bears a very huge torque when the pinion gearbox is running. At the same time, the bearings in the pinion gearbox bear a certain radial force. In order to ensure the normal operation of each transmission element of the pinion gearbox, a dedicated pinion gearbox lubrication channel is designed for the cone crusher. The lubrication system immediately starts to continuously supply oil to the pinion gear box, and the pinion gear box can operate normally under sufficient lubrication conditions after the cone crusher is turned on.

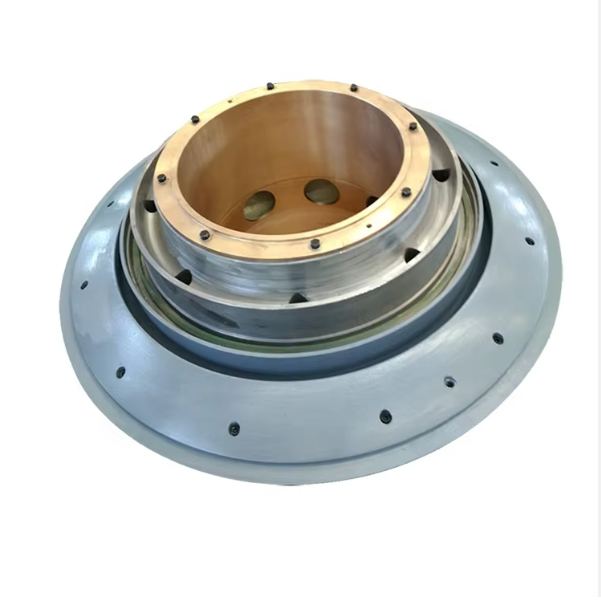

At present, the structure of the pinion gearbox of various cone crushers on the market is similar. No matter which mechanism and type such as Spring cone crusher, multi-cylinder cone crusher, single-cylinder cone crusher, the structure and transmission mode of pinion gear box are basically the same. The body of the small gearbox is made of cast steel, and the main shaft in the box is positioned and matched by two rolling bearings. One end of the main shaft is equipped with a motor pulley, which is connected with the motor through a triangle-belt. The other end of the main shaft is equipped with a small gear, which cooperates with the large gear of the cone crusher to convert torque into crushing force. In short, the pinion shaft is a torque transmitter between the motor and the moving cone, and it performs an important function.

The matching size of the large and small pinions of the cone crusher is extremely important. And the matching clearance of the large and small gears can be adjusted through the positioning adjustment of the small gear box. Experienced operators can accurately adjust the tooth gap, and the cone crusher can be driven smoothly. If the backlash of the pinion box is not adjusted properly, a series of undesirable consequences will occur. First of all, the tooth gap of the small gear box of the cone crusher is too large, and the transmission noise will be very high when the crusher is running. The larger the tooth gap, the greater the noise. Secondly, if the backlash of the pinion gearbox is too small or even the tooth surface is exposed to force, the strong rotating torque after the cone crusher is started may cause component damage. It is generally not recommended that users disassemble the pinion gearbox, unless the transmission shaft and bearings are damaged, it is generally not recommended to open the pinion gearbox for maintenance. As long as the lubrication system is normal and the quality of the lubricating fluid is ensured, the pinion gearbox can basically operate without maintenance.

The bearings of the pinion gearboxes of cone crushers mostly use rolling bearings, and there are also design types that use copper sleeve sliding bearings. Based on the experience of mainstream models in the market and operational stability, the use of rolling bearings in the pinion gearbox of cone crushers is more mature and beneficial. From the practical application, the life, stability and reliability of rolling bearings have been affirmed. The more important factor is that rolling bearings have higher transmission efficiency than sliding bearings, and thin oil immersion lubrication is more effective. Shengyuan mining machines all adopt the design mode of rolling bearing. It has been stable and reliable for many years without much bearing damage and failure.