1. Jaw crusher toggle plate Introduction

The toggle plate and toggle plate pad use rolling contact method, and there is little friction under normal use. Only a layer of grease is applied to the contact surface. The whole part is used to adjust the size of the discharge port and compensate the wear between the jaw plate, the toggle plate and the toggle pad.

2. Jaw crusher toggle plate Installation steps

The toggle plate of the jaw crusher is both a safety part and a vulnerable part. It is easy to damage. It should be replaced immediately once the toggle plate is worn or broken. How to replace the toggle plate after it is worn? The following are the installation steps of the jaw crusher toggle plate:

a. To install the toggle plate of the jaw crusher, first loosen the spring nut of the tension rod, and then remove the spring.

b. Use a chain and steel wire to tie the lower part of the movable jaw.

c. Use a professional installation tool to pull the wire with a hand hoist to make the movable jaw close to the fixed plate, and the toggle plate will automatically fall.

d. Use a wire to pull the new bracket into the bracket seat after the old bracket is removed.

e. Then, relax the hand hoist so that the toggle plate and the toggle plate seat are in close contact.

f. Finally, install the pull rod and the spring and the toggle plate is supported in the toggle plate seat, and the hand hoist can be removed.

The above are the installation steps of the jaw crusher toggle plate. The correct installation can reduce the impact of the normal operation of the crushing equipment due to improper installation in the future work, which can also save the time of the jaw crusher for maintenance.

3. Jaw crusher toggle plate Role

a. Transmission power

sometimes the power transmitted is greater than the crushing force.

b. Plays the role of insurance

The toggle plate breaks first when the crushing cavity falls into non-crushing materials (such as drill rods, broken shovel teeth), so as to protect other parts of the machine from damage.

c. Adjust the size of the discharge opening

Some simple toggle jaw crushers adjust the size of the discharge opening by changing the toggle plate of different lengths.

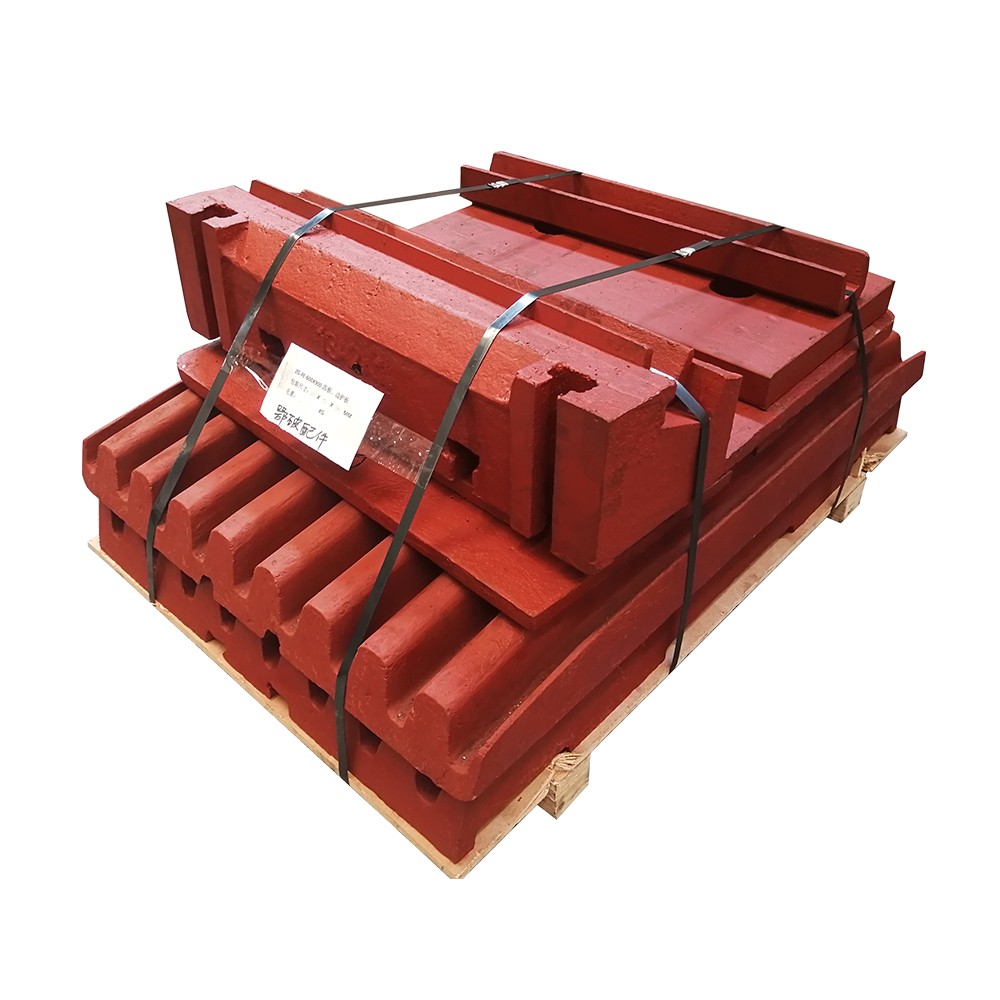

4. Jaw crusher toggle plate Structure

According to the structure, the toggle plate is divided into two types: assembly type and integral type: the toggle plate used in the simple pendulum jaw crusher is an assembled structure. It is assembled by connecting a toggle body and two toggle heads, so that only the toggle heads that are easily worn out can be replaced to save consumable metal. Since the bracket used in the large-scale crusher is heavier, lifting rings should be designed for this bracket. The integral toggle plate is used on the compound pendulum jaw crusher because its weight and size are relatively small.

5. How to design the toggle plate

There are generally two structural forms of elbow head and elbow pad: rolling type and sliding type, which can be selected according to actual needs during design.

1. Change the shape of the mating surface: According to the analysis of the movement of the dobble toggle jaw crusher, it can be seen that the toggle plate movement characteristic is a simple swing, which is a hinged swing piece. Therefore, the elbow and the elbow pad constitute a swing pair. In the work of the crusher, the toggle plate pad is deformed due to long-term impact, and it is difficult to remove it during replacement. Therefore, the problem can be solved by changing the shape of the mating surface.

2. Use better materials: The structure of the toggle plate includes integral and combined. Taking into account the performance requirements at work, the elbow pad bears a great impact and must be made of better materials.

3. Install dust guard: It is not only need inject lubricating oil between the two joint surfaces, but also necessary to prevent dust and fine grain materials from entering the joint for reducing the friction between the elbow pad and the elbow. So It is necessary to install the dust guard on the upper part of the meeting point.