1. The introduction of Shilong jaw crusher jaw plate

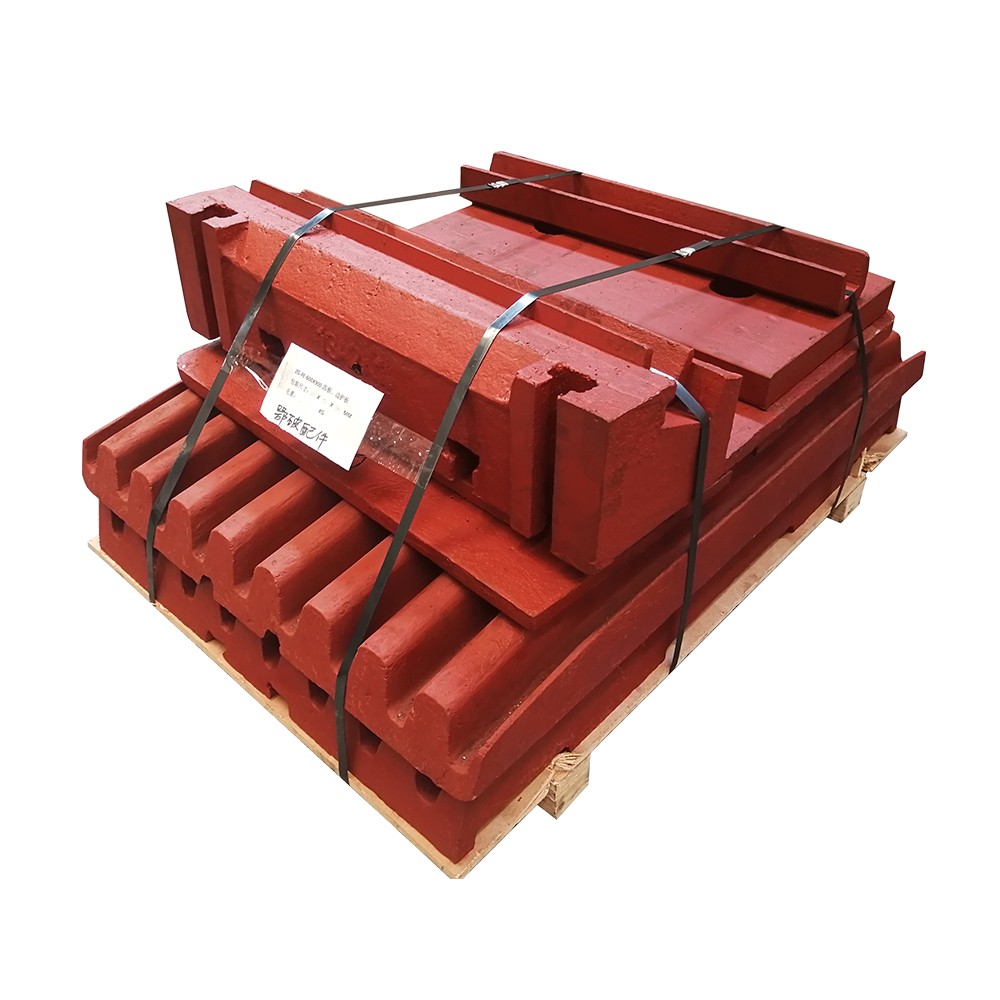

The jaw plate is short for jaw crusher jaw plate. The jaw plate is divided into a fixed jaw plate and a movable jaw plate. It is a wearable part of the jaw crusher. In the operating state of the jaw crusher, the movable jaw is attached to the movable jaw to make a compound movement, forming an angle with the fixed jaw to squeeze the stone. Therefore, the jaw plate is an easily damaged accessory (abbreviation: vulnerable part) in the jaw crusher.

2. The role of the jaw plate of Shilong jaw crusher

The jaw plate is the main wear-resistant part of the jaw crusher: the movable jaw plate and the fixed jaw plate. According to the different types of the jaw crusher, there are a variety of models and sizes. The jaw plate is made of new high manganese steel, super high manganese steel, Super high manganese steel and other materials which are suitable for jaw crushers of various specifications.

The wear speed of the upper and lower parts of the crushing plate is different in their working. The lower part wears faster than the upper part. The crushing plate directly contacts the material and bears huge crushing force and friction of the material when the jaw crusher is working. So the service life of the crushing plate is directly related to the work efficiency and production cost of the jaw crusher. Therefore, it is particularly important to extend the service life of the crushing plate of the jaw crusher. Strengthening the service life of the jaw crusher's crushing plate can be considered from the aspects of design, material selection, assembly, and improvement during use.

The biggest consumption in the production of a crusher is the jaw, so the quality must be checked in the selection of talents. It can also be said that the quality of a crusher is actually based on the service life of the jaw plate. The shell is generally not easily damaged.

3. The performance characteristics of the jaw plate of Shilong jaw crusher:

a. Manganese steel alloy is selected, with high wear resistance and long service life.

b. Using cold work hardening technology, high hardness.

c. Water toughening treatment avoids the deterioration of performance due to natural phase change during use.

d. Before leaving the factory, the laboratory and quality inspection departments must undergo strict random inspections to ensure the quality.

4. Jaw plate design of Shilong jaw crusher

The toughness of manganese steel is good. Although the hardness is not high (about 210 HB), but because of the characteristics of cold work hardening, it will continue to be strengthened under pressure, so it will continue to wear and continue to strengthen during work until it is worn out. Use it to be scrapped. After casting, the manganese steel crushing plate must be treated with water toughening. The operation of the water toughening treatment is basically the same as that of quenching, that is, the cast manganese steel crushing plate is heated to 1 000 to 1 100 ℃ and then rapidly cooled in water.

5. Improved series of jaw plate of Shilong jaw crusher

In the production process, the direct force between the material and the jaw plate is very large, especially when the material with high hardness is crushed. It will cause the bolts of the jaw plate to vibrate and the nuts to loosen, which will increase the wear of the jaw plate and generate great noise. The jaw plate falls off or breaks, causing the equipment to stop, affecting normal production. In this case, just tightening the nuts and bolts before starting the machine can not completely solve the problem. It is necessary to analyze the specific problems according to the actual situation on the spot, and find ways to solve the problem with practical methods.

For example, a spring anti-loose and vibration damping device can be used to solve the loosening of the jaw plate during work, thereby prolonging the service life of the crushing plate and improving work efficiency. The specific method is to use a spring to make a bolt anti-loosening and self-tightening device. The device is composed of an inner spring gland, an outer spring, and a spring gland. Put this device on the bolt to tighten the nut, because the spring is compressed to a certain extent by the nut After that, a strong anti-vibration effect is produced. The bolt loosening force generated by the huge crushing force is automatically compensated by the spring tension force, so the bolts will not be loosened, thereby extending the service life of the jaw plate and improving production efficiency. In short, in the process of use, we can find ways to solve specific problems according to specific conditions, prevent increased wear, loose jaws, breakage, etc., so as to extend the service life of jaws, reduce costs, and improve work efficiency.