1. Precautions for the use of the big gear of the cone crusher

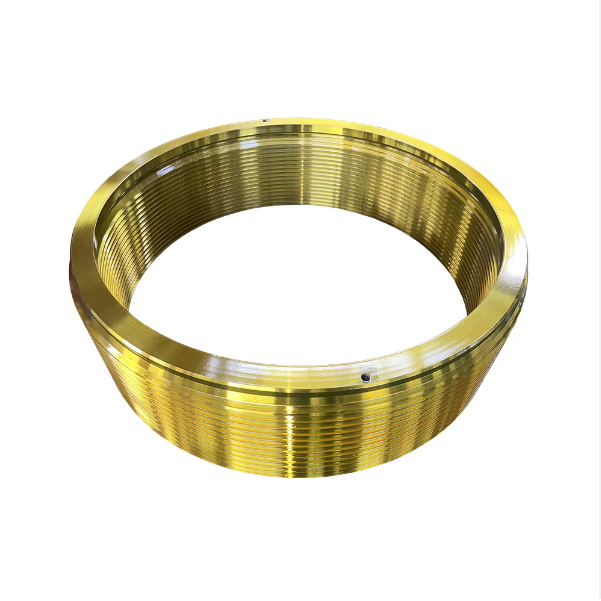

a. It is advisable to pass a 3~4mm gap between the teeth when adjusting the working gap between the small gear and the large gear.

b. Try to ensure that the indexing outer circles of the big gear and the small gear are tangent.

c. If the big gear and counterweight are separate structures, you must align the counterweight with the hollow eccentric shaft and then assemble after installing the big gear; if the big gear and counterweight are integral structures, they also need to be aligned during hot assembly mark.

d. The counterweight needs to be aligned with the transmission part to measure the movable gap when adjusting the gap of the large gear.

2. Analysis of the reasons why the large and small pinions of the cone crusher wear quickly or even break the teeth

Cone crusher is a kind of crusher widely used in production. During its work, some common faults are unavoidable. Large and small bevel gears wear quickly, and it is a common fault that teeth break frequently. The main reasons for this failure are as follows:

1) The normal meshing condition of the bevel gear is destroyed

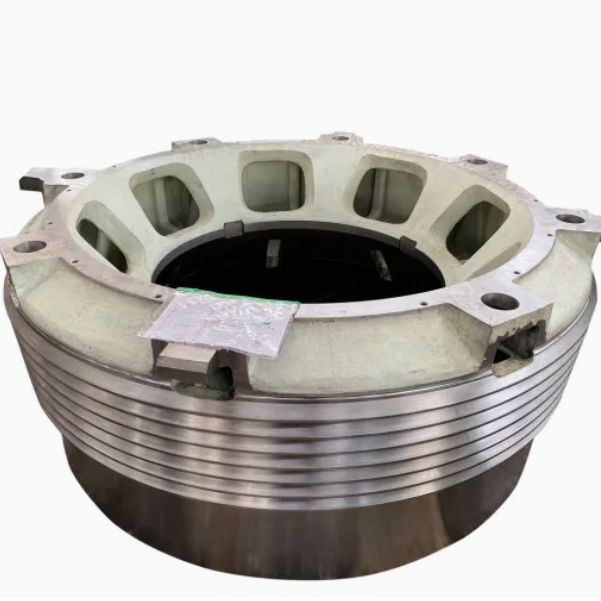

The transmission principle of the cone crusher: the asynchronous motor drives the small bevel gear integrated with the gear shaft, and the small bevel gear drives the large conical gear integrated with the eccentric shaft. The main shaft with taper and integrated with the moving cone body Driven by the eccentric main shaft, its axis takes the center of the spherical bearing as the apex and makes a cone movement around the center line of the crusher to achieve the purpose of crushing ore.

Due to the eccentricity and the strong centrifugal action of the counterweight during the rotation of the cone crusher eccentric shaft sleeve, the thick side is always pressed on the frame bushing, while the thin side always keeps a certain gap with the frame bushing. Therefore, the large bevel gear does not rotate around its own centerline during the rotation, but takes the half of the gap a (a/2) of the frame bushing as the radius. Make a circular motion around the center line of the crusher.

For a pair of bevel gears to mesh normally, the cones of the two gears must meet at one point. And the pitch circle coincides. The special operating state of the large bevel gear destroys the normal meshing relationship of a pair of bevel gears. Therefore, a large impact load and sliding friction are generated on the tooth surface of the gear during operation, resulting in impact load, wear or breakage of the large and small bevel gears. The phenomenon of teeth is more common.

2) Rigid connection transmission

The transmission form of the cone crusher: the asynchronous motor is rigidly connected to the gear shaft through the elastic coupling. When the cone crusher is over-iron or overloaded, it is easy to cause the large and small cone gears to break.

3) Frequent iron passing or being bitten by large pieces

When iron is sometimes excessive in the ore, although the spring of the crusher plays a protective role, it will often cause the spring to fail when the iron is frequently excessive or bitten by a large piece, resulting in damage to other parts of the machine body, such as large and small bevel gears.