1. Precautions for the use of cone crusher hopper

a. Check the feeding hopper regularly. If the wear level is serious, it needs to be replaced immediately.

b. Rubber belt can be added to the outer edge of the hopper to reduce noise and vibration.

2 . The manufacturing method of the cutting buffer hopper of the cone crusher

Cone crusher is suitable for the crushing of raw materials in metallurgy, construction, road construction, chemistry and silicate industries. According to different crushing principles and different product particle sizes, they are divided into many models. Crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The cone crusher has large crushing ratio, high efficiency, low energy consumption, uniform product size, suitable for medium and fine crushing of various ores and rocks.

Due to the different sizes of ores and rocks, if larger ores and rocks are put into a crusher with poor crushing ability, it will affect the normal use of the crusher, burden the crusher and reduce the service life of the crusher. Increase production costs. In addition, due to the unreasonable setting of the hopper structure, the stone material will also have the problem of uneven cutting.

In order to solve the deficiencies in the above technical problems, a cone crusher cutting buffer hopper is provided, which can sort the stones and make the cutting more uniform.

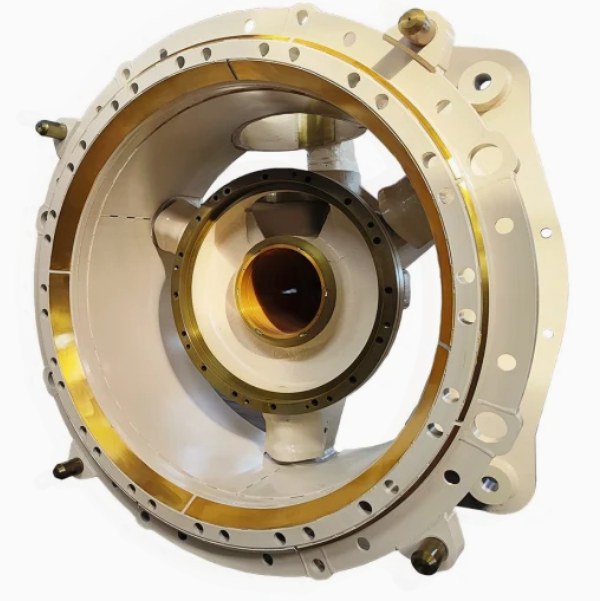

Provide a buffering hopper for the cone crusher, including the machine body. It is mainly equipped with a hopper, a distribution plate, a fixed cone, a moving cone, a main shaft, an eccentric sleeve, and a power device. The middle of the funnel body forms a feed port, the lower end of the arc-shaped sliding wall is provided with multiple discharge channels, the discharge channel passes through the funnel body, the outlet of the discharge channel is located outside the hopper, and the discharge channel is provided with multiple lower A buffer ball is set at the lower end of the material outlet and the discharge channel.

The arc-shaped sliding wall protrudes toward the middle of the feeding chamber.

The discharging channel is set obliquely, and the inclination angle is 30-50 degrees.

The cushion sphere is filled with elastic medium.

Elastic medium is filled between the arc sliding wall and the funnel body.

The elastic medium is asbestos.

Advantages: sort the stones, reduce the crushing burden of the cone crusher, and increase the service life of the cone crusher.

In addition, the discharge channel and the unloading port are evenly distributed, and the reasonable setting can make the unloading more uniform and improve the work effectiveness.