We provide a pressurized release device for the cone crusher, which enables the cone crusher to crush the higher hardness raw materials mixed in the raw materials without replacing the hydraulic cylinder, which saves costs, improves production efficiency, and facilitates popularization and application.

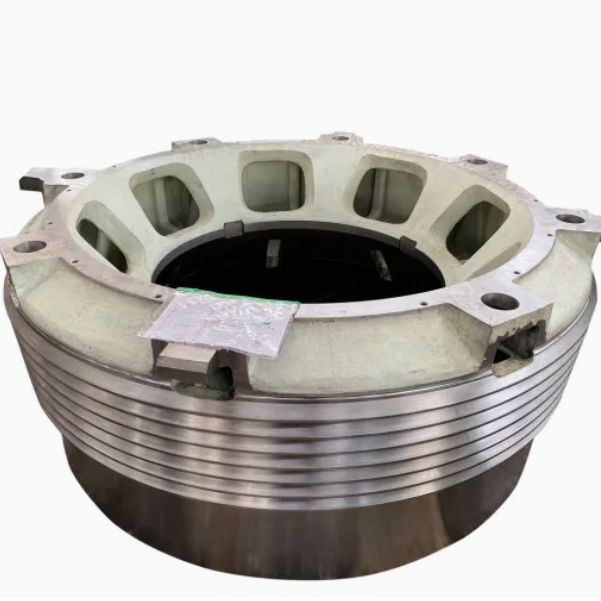

The pressurization release device includes a hydraulic cylinder, a tension rod, a positioning sensor, an airtight solenoid valve, a liquefied gas accumulator, and a microprocessor. A pressure push rod is installed in the hydraulic cylinder. The top end of the hydraulic cylinder is extended. The hydraulic cylinder is provided with a positioning sensor at the outlet position ring of the tension rod. The side of the hydraulic cylinder is connected with a liquefied gas accumulator through an airtight solenoid valve. The micro processing is connected, the micro processing is arranged on the side of the hydraulic cylinder, and the microprocessor is connected to the positioning sensor.

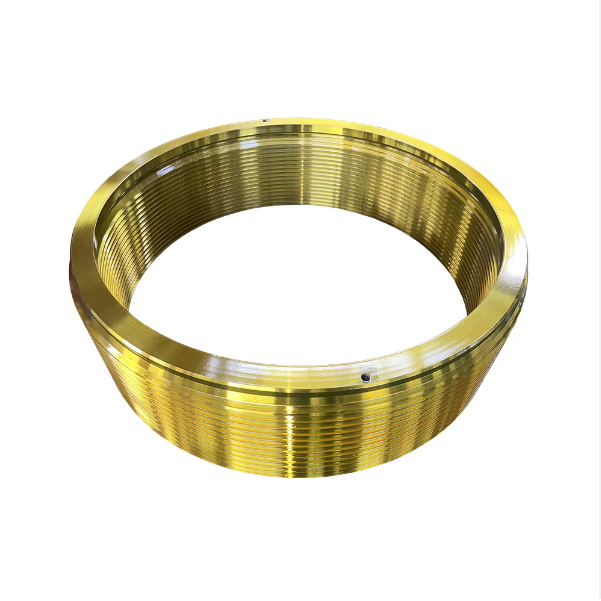

A light-sensitive scale is axially arranged on the outer side of the tension rod, and the light-sensitive scale and the positioning sensor have an internal and external corresponding relationship, and the light-sensitive scale is provided with a fluorescent scale.

The liquefied gas accumulator is filled with liquefied nitrogen, and the airtight solenoid valve is a throttle solenoid valve.

The hydraulic cylinder is provided with a booster cavity and an oil pressure cavity. The booster cavity is connected with the liquefied gas accumulator. The booster cavity and the oil pressure cavity are connected by a booster piston, which can move up and down along the inner wall of the hydraulic cylinder , The oil pressure chamber is connected with the tension rod.

A pressure relief hole is arranged on the side wall of the pressurizing cavity, and a pressure relief solenoid valve is installed on the pressure relief hole, and the pressure relief solenoid valve is connected with the microprocessor.

By combining hydraulic cylinders, tension rods, positioning sensors, air-tight solenoid valves, liquefied gas accumulators, and microprocessors, the cone crusher can be tested and optimized without replacing the hydraulic cylinders. The higher hardness raw materials mixed in the raw materials are crushed, which saves costs, improves production efficiency, and facilitates popularization and application.