1. Precautions for the use of mantle

a. When installing the mantle, it is necessary to pay attention to the installation surface of the bottom processing to fit tightly, and seal the outside with a rubber strip or butter.

b. You need to tighten the conical head and install the toothed gear after installing at the bottom.

c. Try to make the resin fluidity and dry quickly when pouring epoxy resin.

d. Pay attention to the degree of wear of the mantle to prevent wear and leakage.

e. The debris on the outside of the mantle needs to be cleaned when removing the mantle.

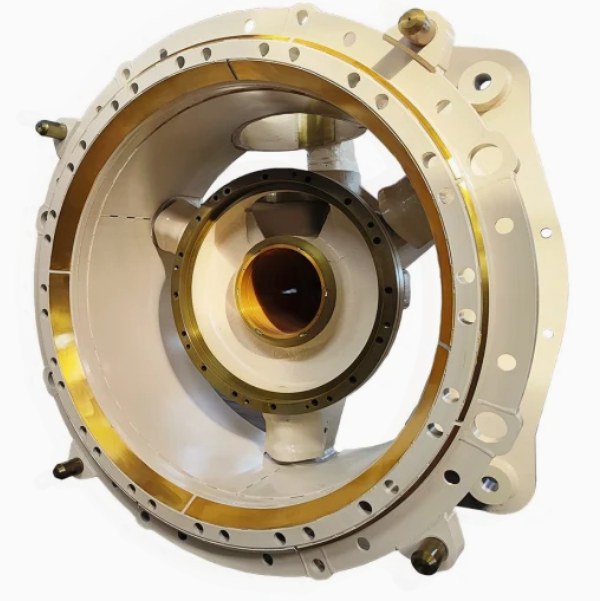

2. How to replace the mantle of the cone crusher

For the cone crusher, some internal parts are easy to wear. When the wear is serious, they need to be replaced to restore the working performance of the equipment. The mantle is one of the parts of the machine. If it is in use, If there is improper operation or excessive hardness of the material, it is easy to cause damage to the part. At this time, it needs to be replaced. Here is how to replace it.

Step 1. Before replacing the mantle, in order to avoid accidental injury to the operator due to splashing water vapor during the pouring process, the liner, body or adjusting sleeve of the cone crusher should first be evenly preheated;

Step 2. After preheating, apply a thin layer of lubricating oil to the inner surface of the equipment liner, the body or the contact surface of the adjustment sleeve, which can not only avoid moisture, but also avoid the zinc alloy and the liner, the body or the surface of the adjustment sleeve Adhesion on

Step 3. After the above operations are completed, put the mantle on the cone and adjust the position, and then use suitable tools for pouring. After the zinc alloy is solidified, carefully clean the end surface of the crushing wall and other surfaces of the cone crusher. After finishing these operations, install the pressure sleeve, pressure cap, sealing ring, pressure cover, and conical head in place;

Note: The mantle of the cone crusher is fixed on the cone by the cone head, and zinc alloy is cast between the two. Therefore, after the newly replaced moving cone has been working for 6-8 hours, the tightening condition should be checked and the looseness should be found immediately Fasten, and this part will also cause runaway due to insufficient oil pressure or poor oil supply in the oil circuit. In order to avoid such things from happening, check the oil pump oil pressure, oil quality, filter and other parts in time to keep the oil The pressure reaches the specified pressure, the pipeline is cleaned to make the oil supply unblocked, and the eccentric sleeve is often measured to make the working gap between the eccentric sleeve and the eccentric shaft within the specified range. These operations are to reduce the damage to the mantle and reduce its impact on the cone.