-

Home

-

Products

-

Cone Crusher

-

Symons Cone Crusher

-

Single Cylinder Hydraulic Cone Crusher

-

GP Cone Crusher

-

Multi-cylinder Hydraulic Cone Crusher

-

HP Cone Crusher

-

Spring Cone Crusher

-

Compoud Cone crusher

- Jaw Crusher

-

PE Jaw Crusehr

-

C Series Jaw Crusehr

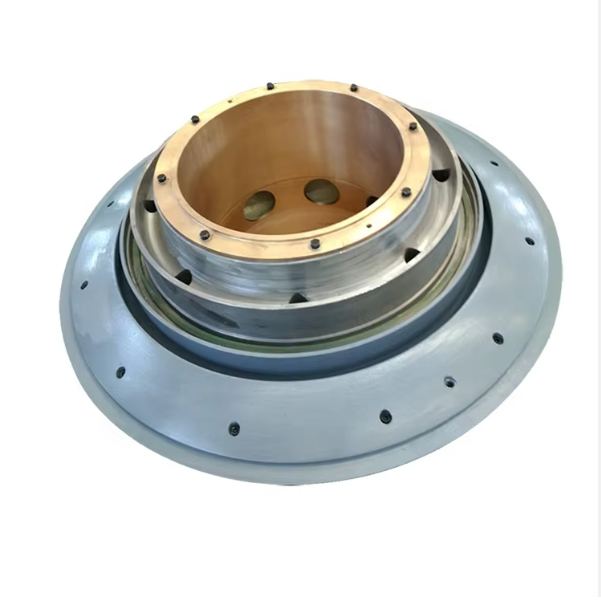

- Cone Crusher Parts

-

Jaw Crusher Parts

- High Pressure Grinding Rolls

-

Vibrating Screen

-

Ball Mill

-

Ball Mill Parts

-

Cone Crusher

- News

-

Case

- Factory Show

-

Contact Us

-

About Us

- Certificate

- Exhibition

-

FAQ

- Is your company a manufacturer or an international trade company?

- What kind of production equipment does your company have? What is the technical strength?

- What are your main products? And any advantages?

- Any advantages in product testing for Shilong Product?

- Any advantages in terms of production period and price?

- What is your shipping and payment method?

- Does your company have stock for these spare parts ?

- Service

- Delivery