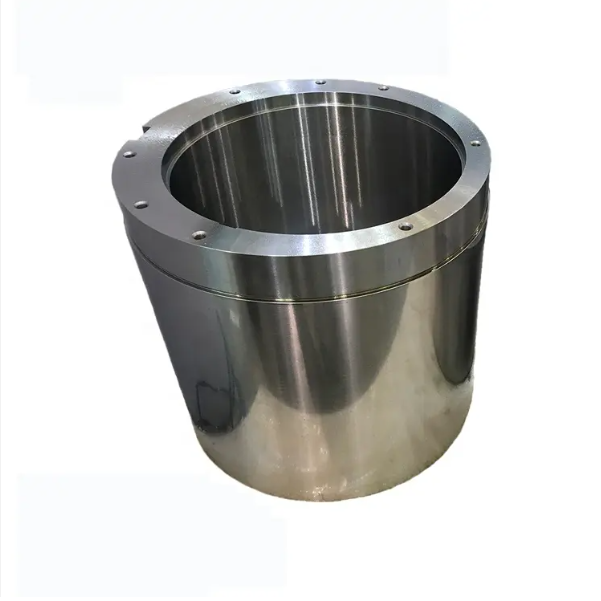

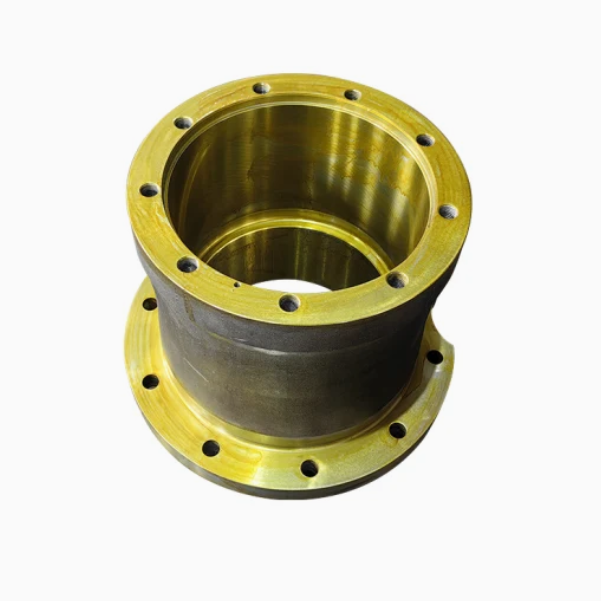

The Single Cylinder Hydraulic Cone Crusher Eccentric is equipped with a high-lead bronze bushing fixed by screws; the lower part is equipped with a large bevel gear and a thrust bearing through a bolt. The upper thrust bearing is forged steel, and the lower thrust bearing is high-lead bronze Lining set; In addition, bolts can also be used to fix the counterweight component on the eccentric shaft sleeve, the inside of which is filled with lead and a wear-resistant protective liner is installed.

1. Single Cylinder Hydraulic Cone Crusher Eccentric Exercise status analysis

a. When there is no balance counterweight or the balance counter weight is light, the thin side of the main shaft of the crusher and the eccentric bushing is sleeved on the left side of the straight bushing;

b. When the balance counterweight is heavy, the main shaft of the crusher is on the thin side of the eccentric bushing, and the eccentric bushing is on the right side of the straight bushing;

c. The inertial force of the moving cone is completely balanced. This ideal situation does not exist.

2. GP Cone Crusher Eccentric

When the cone crusher is working normally, under the action of the crushing force, the moving cone main shaft and the eccentric shaft sleeve are both leaning on the right side of the straight bushing. This is because when the crusher changes from no-load to band-load operation, it will inevitably produce an impact.

a. In production, the concentrator requires a smaller discharge port to obtain a product with a smaller particle size. Therefore, the fine crusher must adopt the second movement state, which is to install a balance above the large bevel gear of the eccentric shaft sleeve Weight and make the moment to the center of the sphere 0;

b. Under no load, the main shaft rests on the thin side of the eccentric sleeve, and the thick side of the eccentric sleeve is pressed against the straight bush; when loaded, the main shaft rests on the thick side of the eccentric sleeve and the thin side of the eccentric sleeve Press on the straight bushing. In this way, the harmful effects of inertial force and moment of inertia on the vibration of the machine base and the operation of the machine can be weakened, so as to achieve the purpose of balancing the crusher.

3. Single Cylinder Crusher Eccentric Preparation before installation

a. You need to check all the parts to be installed before installing the eccentric shaft sleeve of the cone crusher.

b. Install the adjustment pad on the bottom cover, and then install the thrust bearing on the adjustment pad in order. It is especially important to note that the boss of the bottom pad should be stuck in the groove of the bottom cover for firmness.

c. Fix the top pad of the thrust bearing of the cone crusher on the eccentric shaft sleeve with a screw, and then use the special lifting lugs on the gear to install it into the sleeve.

4. Single Cylinder Hydraulic Cone Crusher Eccentric Precautions before installation

a. Install the boss firmly in the groove of the bottom cover.

b. The top pad of the thrust bearing of the cone crusher should be fixed on the eccentric shaft sleeve.

5. Single Hydraulic Cone Crusher Eccentric during installation

a. Carefully check the gap between the eccentric shaft sleeve of the cone crusher and the straight bushing of the frame, and the upper and lower gap between the main shaft and its shaft sleeve.

b. The gap between the eccentric bushing and the straight bushing is consistent up and down.

c. Please measure the meshing gap of the gear by pressing the lead or rotating the shaft after the eccentric sleeve and bevel gear are installed in the frame.

6. GP series Cone Crusher Eccentric Causes of wear

Severe wear of the journal and eccentric section journal, excessive bending of the axis and fatigue fracture, will cause the wear of the eccentric shaft; the crusher with sliding bearing is prone to wear of the eccentric shaft; the contact area of ??the taper sleeve and the mating surface of the eccentric shaft is less than 80% , It is easy to cause the taper sleeve to loosen on the eccentric shaft. The outer circle of the eccentric shaft and the inner hole of the taper sleeve will wear out at the same time once loosened.

7. Single Cylinder Hydraulic Cone Crusher Eccentric Repair method

Worn journal turning: On the premise of ensuring the design surface roughness, use the smallest processing amount to process, and then use the processed journal size and deviation as the reference, and prepare the bearing according to the original design matching performance.

Axle journal insert sleeve: Turn the worn axle journal off and make another steel sleeve. Red Star Heavy Industry reminds users that the inner hole of the steel sleeve and the journal should be an interference fit, and the outer diameter should be processed according to the original design size and tolerance. Also note that the steel sleeve should be hot-fitted to the journal.

Surfacing of the journal surface: use manual arc welding to surfacing the journal surface, and then perform cutting to achieve the original design journal size and deviation. And to ensure that the eccentric shaft does not produce bending deformation. When repairing welding, care should be taken to select the type of welding rod, the smallest and best surfacing current, the diameter of the electrode should be as small as possible, and the symmetrical cycle surfacing. During surfacing welding, attention must be paid to avoid local overheating to prevent deformation, and the centering datum should be selected reasonably during processing to maintain the operation accuracy after assembly.