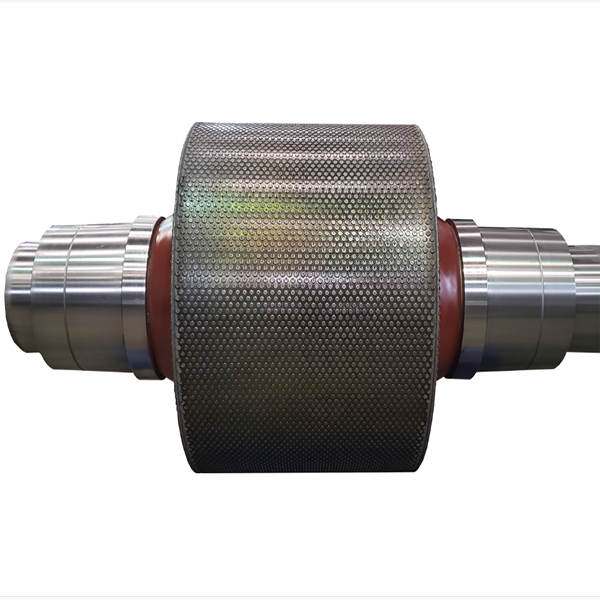

Product Introduction:

GM series mining high pressure roller mill is a new product developed by our company through technological innovation based on the technology of a German company. The equipment consists of two squeezing rollers rotating in opposite directions. The material is fed from above the two rollers, and is crushed between the materials under the high pressure of the squeezing rollers, and then discharged into dense cakes. It is now mainly used for non-ferrous metal ores such as bauxite, iron ore, iron ore concentrate, and finely crushed cement raw materials, clinker, blast furnace slag, limestone and other materials.

Advantages and Features:

1. Using high pressure roller mill in the process flow of the grinding system can improve the production efficiency of the entire system by 20% to 30%. At the same time, the total power consumption of the grinding system can be reduced by 25 to 50% compared with the traditional grinding method;

2. This product is equipped with a sealed roller cover, which can strictly control the diffusion of harmful dust and create an excellent production environment;

3. Compact structure, small footprint, high reliability, and the operating rate can reach about 95%;

4. This product has low energy consumption and low pollution, and is a product series that responds to energy conservation, emission reduction, low carbon and environmental protection;

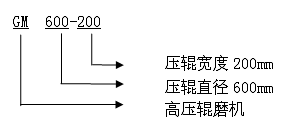

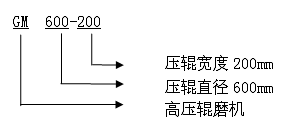

Model Description:

Ordering instructions:

1. Material characteristics, material input and output requirements, and output requirements should be clearly stated in the contract;

2. Assembly is generally supplied in right-hand mounting. If left-hand mounting is required, it must be noted in the contract;

3. The standard configuration does not include an electrical control system. If required, it must be noted in the contract;

Technical parameters:

型号

| 压辊直径 mm | 压辊宽度 mm | 电机功率 kw | 入料粒度 | 产品粒度 | 通过量 t/h | 近似重量 t |

|

金属矿石 mm | 铁精粉 cm2/g | 金属矿石 mm | 铁精粉 cm2/g |

|

| GM600-200 | 600 | 200 | 2X75 | ≤25 | 1100-1300 | ≤3 | 1400-1600 | 16-24 | 14 |

| GM800-350 | 800 | 350 | 2X132 | ≤30 | 1100-1300 | ≤3 | 1400-1600 | 39-58 | 24 |

| GM1000-300 | 1000 | 300 | 2X160 | ≤35 | 1100-1300 | ≤3 | 1400-1700 | 61-91 | 32 |

| GM1000-400 | 1000 | 400 | 2X200 | ≤35 | 1100-1300 | ≤3 | 1400-1700 | 80-120 | 36 |

| GM1000-500 | 1000 | 500 | 2X280 | ≤35 | 1100-1300 | ≤3 | 1400-1700 | 100-150 | 40 |

| GM1200-500 | 1200 | 500 | 2X315 | ≤40 | 1100-1300 | ≤3 | 1600-1800 | 130-190 | 56 |

| GM1200-630 | 1200 | 630 | 2X400 | ≤40 | 1100-1300 | ≤3 | 1600-1800 | 160-240 | 65 |

| GM1200-800 | 1200 | 800 | 2X500 | ≤40 | 1100-1300 | ≤3 | 1600-1800 | 200-310 | 79 |

| GM1400-800 | 1400 | 800 | 2X560 | ≤50 | 1100-1300 | ≤3 | 1600-1800 | 260-390 | 110 |

| GM1400-1100 | 1400 | 1100 | 2X800 | ≤50 | 1100-1300 | ≤3 | 1600-1800 | 360-540 | 133 |

| GM1700-1100 | 1700 | 1100 | 2X1000 | ≤60 | 1100-1300 | ≤3 | 1600-1800 | 530-800 | 179 |

| GM1700-1400 | 1700 | 1400 | 2X1250 | ≤60 | 1100-1300 | ≤3 | 1600-1800 | 670-1000 | 208 |