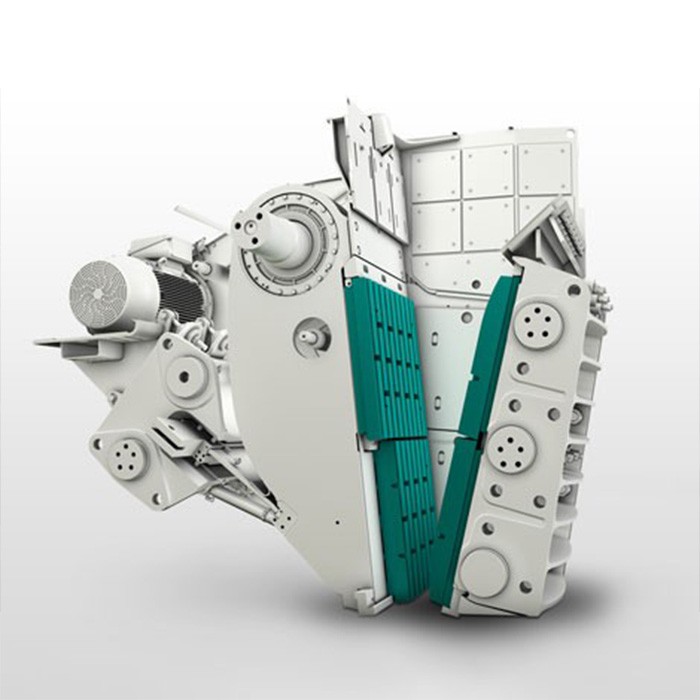

1. Product overview of Shilong C series jaw crusher

The C series jaw crusher is a new generation of jaw crusher developed in cooperation with ALTAIRAC with theintroduction of French technology. Compared with similar models, it has high output, low energy consumption, reliable structure, easy operation and maintenance.It is the preferred equipment for coarse crushing of various rocks.

For over 45 years, C series jaw crushers have been proven to have high reliability in different coarse crushing operations in mines and recycling. The global installed capacity is as high as 11,000. Its pin and bolt connection and non-welded frame structure, as well as the double wedge discharge opening adjustment system, are still in use today to help customers achieve production goals in crushing operations. Where does the C in the name of the product series come from?

The market responded well when the C series was launched. Part of the reason is that the early C series jaw crushers are 30% lighter than other crushers on the market, but they are also robust and reliable. Of course, just like other new products in this demanding industry, the crusher has also been fine-tuned based on customer feedback.

The main design principle of C series kinematics is to improve efficiency by speeding up the work cycle. Customers and sales staff have noticed this because the sound and rhythm of the crusher have changed; the speed of the crusher is higher than any previous model . Even in the early days, high crushing ratio and high productivity were the characteristics of C series crushers.

Over the years, C series jaw crushers have been improved and optimized many times. For example, the development of 3D design capabilities has promoted FEM (Finite Element Method) calculations, and digital signal processing and mathematical operations have achieved crushing simulation. Deeply understand the inner core of the jaw crusher, and further develop the design and operation of the crusher. However, the original pin-and-bolt connection design principles in the 1970s are still in use today.

2. Performance characteristics of Shilong C series jaw crusher

Due to the unique design of the jaw crusher's feed port, the crushing cavity has a V-shaped cavity structure, so the feed size is larger, and the discharge port is also hydraulically adjusted. The specific features are as follows:

① The cavity type adopts the V-shaped crushing cavity, which has a processing capacity of about 1.15 times larger than that of the ordinary cavity type, saving energy consumption by more than 10%.

② The shape and size of the movable jaw plate and the fixed jaw plate are exactly the same, and they can be used for multiple U-turns, which can greatly reduce the spare parts inventory and the number of spare parts purchased by the user.

③ As the structure of tooth top to top and tooth bottom to bottom is adopted, the crushed material is confined to the space of a specific shape when passing through the discharge port, which has a shaping effect on the material. Therefore, the discharged material has a better particle shape.

④ This cavity type can achieve complementary wear of the jaws on both sides. When used interchangeably, the utilization rate of the jaws can be greatly improved, the surface of the jaws will wear evenly, and the life of the jaws can be doubled.

⑤ The large inclination angle design of the toggle plate and the adjustable transmission angle structure design can optimize the parameters of the crusher mechanism under different discharge ports. The output can be higher under the same discharge port.

⑥ The combination of the toggle plate and the toggle plate pad adopts an arc structure, which makes the transmission more reliable and can effectively reduce the noise.

⑦ The movable jaw head is designed with a larger inclination angle, which can effectively slide out when encountering materials exceeding the maximum feed size, which can effectively protect the bearing.

⑧ The belt wheel and flywheel are matched with the shaft using a taper fitting, and the frame bearing and the shaft are matched with a withdrawal sleeve structure, which makes disassembly and assembly convenient and quick.

⑨ The discharge port adopts double-jack hydraulic adjustment, which is faster and more labor-saving.

⑩ The movable jaw is designed with a removable structure, which is convenient for transportation.

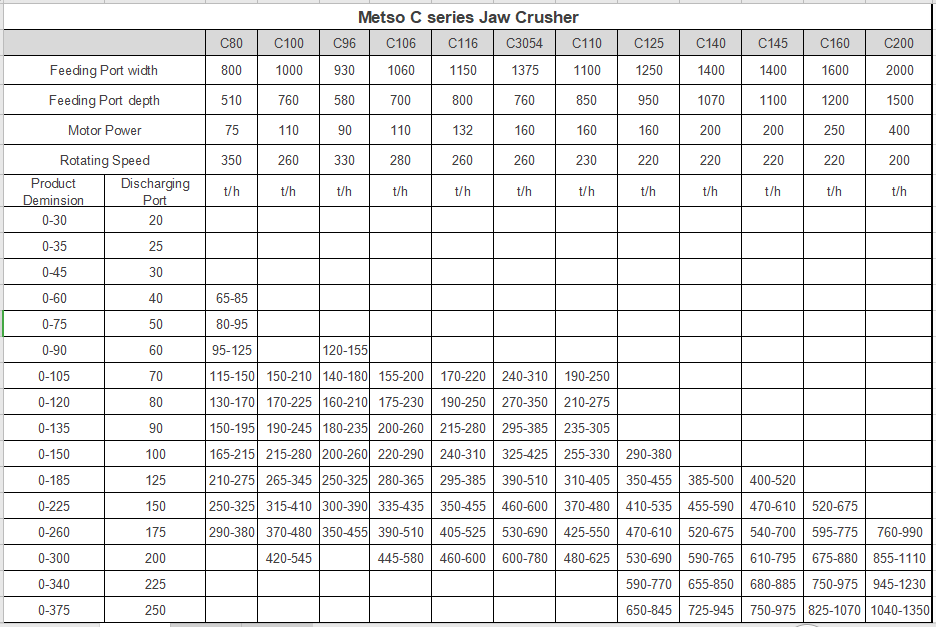

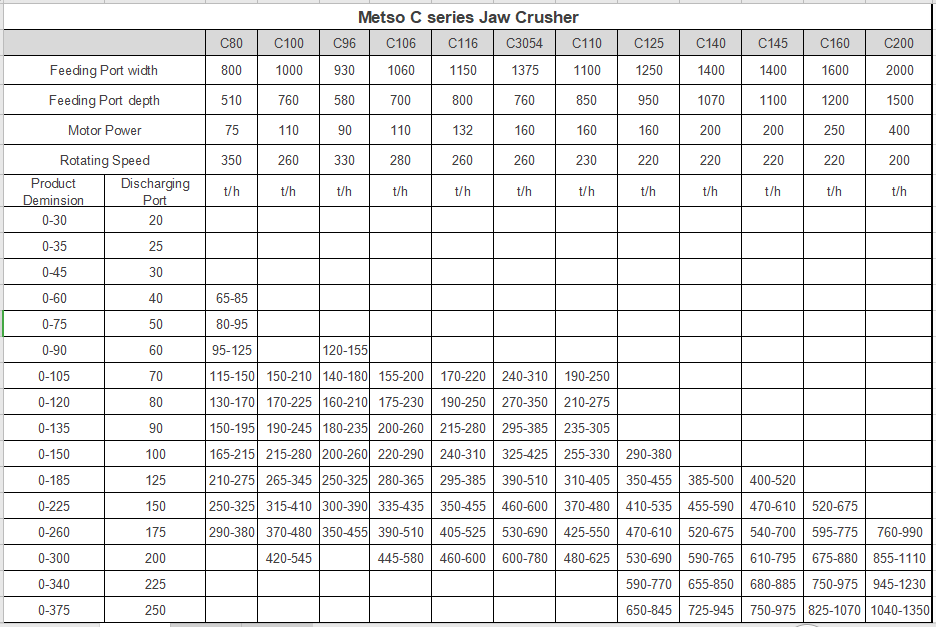

3. Metso C series Jaw Crusher Character Table

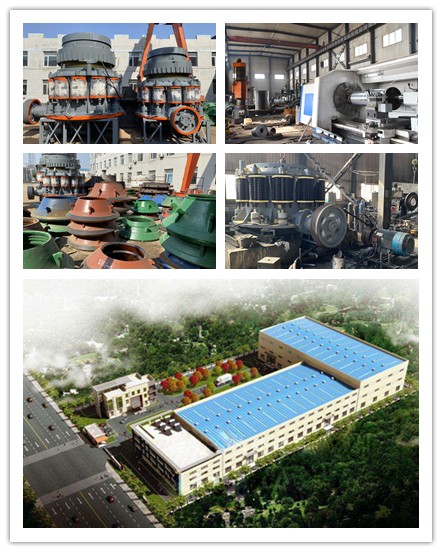

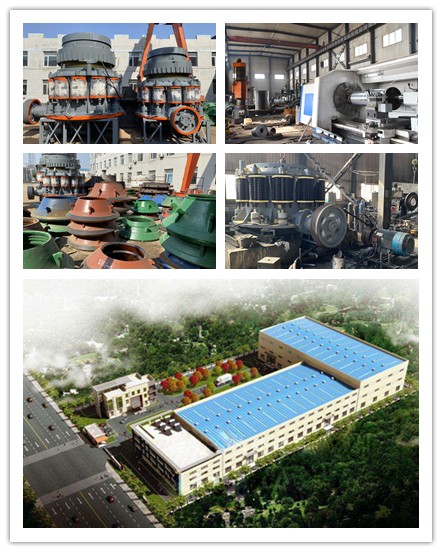

ShiLong Company Profile

Shenyang ShiLong Mechanical Manufacturing Co., Ltd. was established in 2000. It is a comprehensive enterprise dedicated to the production of mining machinery and spare parts.

As a manufacturing enterprise focusing on mining equipment and products, ShiLong is committed to building a global professional manufacturing factory. Shilong has more than 300 lathes, boring machines, milling machines and various CNC processing equipment and has more than 30 professional and technical personnel! And has a large warehouse of nearly 3000 square meters.

For 20 years, ShiLong has manufactured more than 1,000 kinds of mining equipment and related spear parts for more than 3,000 domestic enterprises and foreign trade companies. The products mainly cover multi-cylinder hydraulic cone crusher, heavy hydraulic cone crusher, single-cylinder hydraulic cone crusher, symons cone crusher, jaw crusher, gyratory crusher, ball mill, high-pressure roller mill and their spear parts.

The product quality is reliable, the performance is good, has won widespread praise.

ShiLong looks forward to working with you to create the future together!

ShiLong Company Packing and Transport

Shilong attaches great importance to packaging. Especially products exported to foreign trade.

Before packaging, we will strictly inspect and handle all mechanical parts. Minimize the failure rate of products.

For transportation, we can meet all the transportation requirements of our customers.

Shilong's ultimate goal is to build a world-class professional manufacturing plant. We will work tirelessly for this goal.

ShiLong Company Spare Parts Store

ShiLong has ready-made finished products stored in inventory whose area is nearly 3000 square meters. We can ship directly, eliminating the production period.

For the jaw crusher parts, we can manufacture single toggle jaw crusher, double toggle jaw crusher, mesto c-series jaw crusher,jaw crusher shaft, jaw crusher movable jaw, jaw crusher bearing, jaw crusher toggle plate, jaw crusher toggle plate seats, jaw crusher fixed jaw plate, jaw crusher flywheel, jaw crusher frame, jaw crusher tension rod, etc.

For the cone crsuher parts, we can manufacture symons cone crusher, spring cone crusher,GP series cone crusher, HP series cone crusher, copound cone crusehr, gyratory crusher, and their spare parts including : cone crusher main frame, cone crusher main frame liner, cone crusehr countershaft, cone crusher countershaft bushing, cone crusher countershaft box, cone crusher thrust washer, cone crusher socket, cone crusher socket liner, cone crusher socket sealing ring, cone cruehr pinion, cone crusher pulley, cone crusher main shaft, cone crusher counterweight, cone crusher eccentric , cone crusher innner eccentric bushing, cone crusher outer eccentric bushing, cone crusher step plate, cone crusher feed distributor, cone crusher spring, cone crusher gear, cone crusher adjustment gear, cone crusher adjustment drivend box, cone crusher hydraulic motor, cone crusher adjustment ring, cone crusher adjustment cap, cone crusher head, cone crusher concave, cone crusher mantle, cone crusher relief cylinder, cone cruehr shaft nut cap, cone crusher bowl, cone crusher feed cone, cone crusher hopper, cone crusher baffle ring, cone crusher lubrication system, etc .

For ball mill parts, we can manufacture ball grinder mill, ball mill gear, ball mill pinion, ball mill coupling, ball mill shaft, ball mill reducer, ball mill shell, ball mill liners, ball mill bearing, ball mill bearing seat, ball mill feeder, ball mill feeder cap, ball mill seal ring, ball mill discharge, ball mill discharge cap ball mill bearing cover, etc.

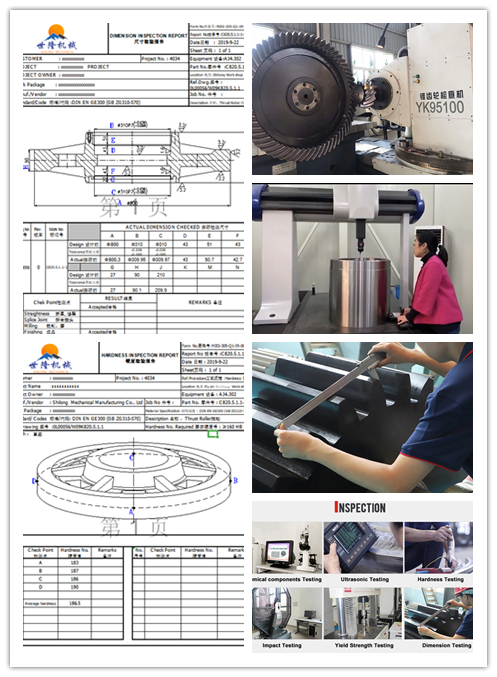

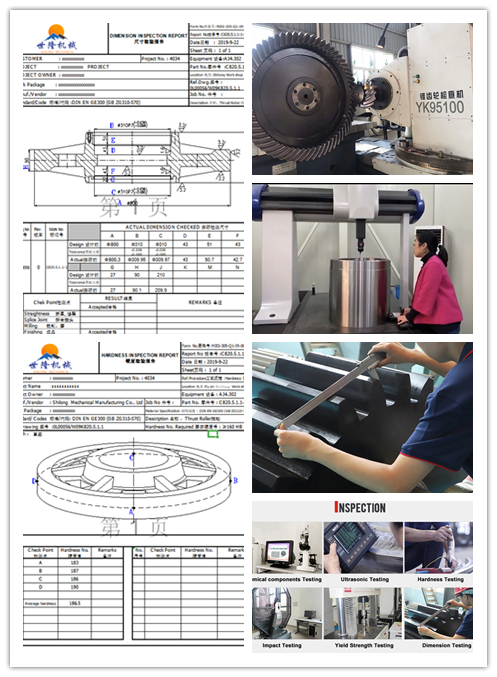

ShiLong Company Inspection

Shilong has over 20 years of experience in the field of crusher and mill spare parts. For product inspection, Shilong requires everyone to implement the principle of one inspection per product and one number per product. There are an independent file and after-sale tracking for each one factory product. We hope to do quality control in every detail.

For every product, For each product, we do strict quality inspection and establish product files. After the quality inspection is completed, we provide an accurate quality inspection report.

We hope to be able to do it truly: Shilong only product high-quality products. And all the products produced by Shilong must be good quality products.